Researchers Combine Carbon Nanotubes with MEMS Technology to Make a Tiny Triode

DOI: 10.1063/1.1506738

Though superseded for most applications by the solid-state transistor, the venerable vacuum tube boasts one big advantage over its younger usurper: power. Free of stuff between its electrodes, a vacuum tube can operate at currents that would ohmically toast a transistor’s semiconducting innards. Vacuum tubes remain the technology of choice for high-power amplifiers, magnetrons, and klystrons.

Now, a team led by Wei Zhu of Agere Systems in Murray Hill, New Jersey, has built a device that could propel the vacuum tube out of its traditional niches. 1 The Agere device, a 100-μm-scale triode, exploits two of the hottest technologies of the past decade: carbon nanotubes and micro electromechanical systems (MEMS). And because the new triode sits on a silicon substrate, it could readily plug into an integrated circuit. Agere developed the triode as a proof of concept. Devices like it could end up in compact wireless transmitters.

Hot and cold cathodes

All vacuum tubes, including the Agere triode, share the same basic components. A cathode emits electrons, which shoot across an evacuated gap toward an anode. Triodes include an additional electrode—the grid—between the cathode and anode. Because it’s placed close to the cathode, the grid can attract or repel electrons with modest changes in voltage, thereby controlling the current across the device.

In traditional vacuum tubes, ohmic heating provides electrons with the energy they need to escape the cathode surface. Though simple, hot cathodes are far from ideal. They can’t turn on rapidly because they have to reach a temperature of at least 800°C. The operating temperature is so high that hot cathodes burn out when the rest of the device could keep going. And because of the heat, you can’t place the grid or anode arbitrarily close to the cathode. As a result, hot cathode devices can’t be easily miniaturized. And the smaller the gap between the electrodes, the higher the frequency of the radiation produced when running the vacuum tube as an oscillator.

The Agere triode uses field-emitting cathodes, which rely on a strong electric field, rather than heat, to release the electrons. As Ralph Fowler and Lothar Nordheim explained in 1928, the field reduces the tunneling barrier so that electrons can easily tunnel out to the cathode surface. 2 Because they’re cold, field-emitting cathodes avoid the pitfalls of their hotter cousins, but getting field emitters to work has its own set of challenges. At 1 gigavolt per meter, the required field to coax emission from most materials is so great that the emitters must be extremely narrow. And to produce enough current, you need a lot of them.

With those aims in sight, in 1970 Capp Spindt of SRI International invented a way to fabricate an array of pointy metallic field emitters using advanced lithography. But, despite 30 years of development, Spindt-type cold cathodes have attained somewhat limited success. The problem lies in creating an array of uniform emitters. Millions of individual emitters make up a typical Spindt-type cathode, but only the 1000 to 10 000 sharpest of them emit. Because these few emitters carry all the current, they tend to fail—sometimes explosively. Another disadvantage is the steep cost of the high-precision lithography needed to fashion the tips.

Nanotubes are cool

Eight years ago, Walt de Heer realized that carbon nanotubes would make superb field emitters. Although nanotube carbon has a high work function, nanotubes have such tiny tips that a field of just tens of volts per micrometer will liberate electrons. De Heer, who’s now at Georgia Tech, and his collaborators, André Châtelain (Ecole Polytechnique Fédérale de Lausanne, Switzerland) and Daniel Urgate (Brazilian National Synchrotron Light Laboratory), built a high-intensity electron gun in 1995 from a dense array of aligned nanotubes. 3

To create their nanotube arrays, de Heer and company drew a suspension of ready-made tubes through a ceramic sieve and then transferred the aligned and upright tubes to a substrate. Since that pioneering work, new methods have emerged for growing aligned nanotubes directly on the cathode. The Agere group used a technique they’d developed two years ago. 4 First, a thin layer of iron is deposited onto what will eventually be the cathode. Iron serves to nucleate the nascent nanotubes, which form when the gaseous reactants, ammonia and acetylene, are vaporized by a strong microwave field. Under the influence of the field, the nanotubes grow quickly and evenly in thick, dense arrays like a bamboo grove. Turning off the field halts the growth and controls the height of the tubes.

Pop-up triode

To build their triode, the Agere researchers exploited a MEMS technique called surface micromachining. The technique’s practitioners assemble devices in a series of patterned layers of various materials, usually forms of silicon, such as polysilicon, silicon dioxide, and silicon nitride. Micromachinists etch away oxide layers to leave behind intricate threedimensional structures on the substrate, just as a sculptor breaks apart a plaster mold to reveal the cast metal sculpture inside. (For more on MEMS, see the article on page 38 of the October 2001

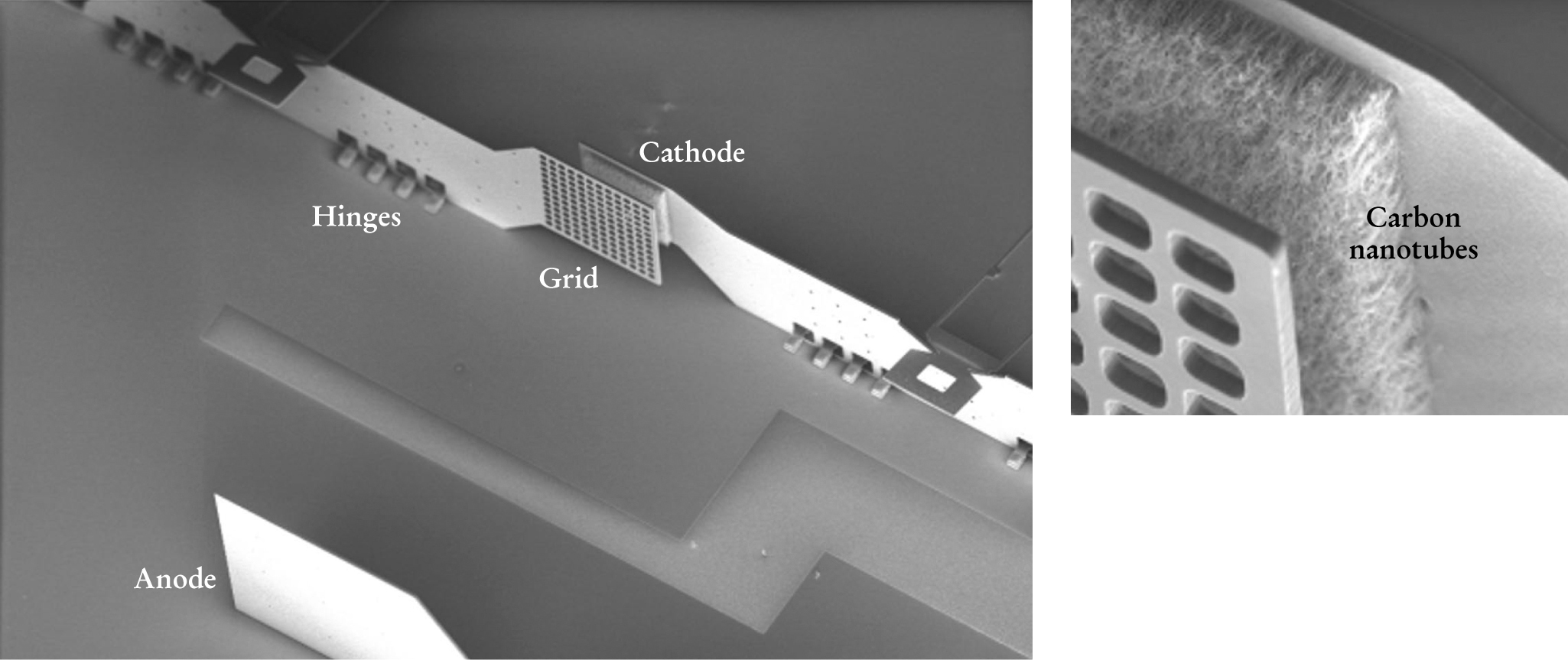

But building vertical structures in layers takes time. As a short cut, MEMS engineers create pop-up structures. Pioneered 10 years ago by Kris Pister of the University of California, Berkeley, pop-up fabrication involves micromachining structures that resemble the hatches on ships. First, the structure, lying flat and replete with hinges, is patterned. Next, the layer beneath the structure and around the hinges is etched away. Pop-up structures can be engineered to spring upright spontaneously once the underlying layer disappears. But for their triode, shown in the accompanying figure, the Agere researchers chose instead to raise the three electrodes by hand under a microscope.

Other ideas

The Agere team developed the triode as a proof of concept, rather than as a production prototype. The triode shows the expected field-emitting behavior and amplifies the grid current by a significant, but modest, factor of four. However, the team couldn’t run the triode in AC mode as a microwave generator because too much current is lost each cycle to capacitance that strays into the circuit from the base of the device. With an optimized choice of materials, a triode of about the same dimensions should, the Agere team calculates, operate close to 200 MHz.

In the vacuum tube marketplace, pentodes and induction-output amplifiers, not triodes, are the biggest money earners. The Agere team has already built a pentode, but the biggest challenge remains: to build a microwave device that can operate at the 1–2 GHz frequencies used in wireless communications.

The basic concept behind the Agere triode, controlling the flight of ballistic electrons in minuscule settings, offers other possibilities. David Garner of University College London envisions creating a tiny UV light source by sending a beam of electrons through a low density gas, such as nitrogen. Ionized by the electrons, the atoms would deexcite by emitting UV photons, just like a fluorescent light bulb. Dan Nicolaescu of Romania’s National Institute for Research and Development in Microtechnologies has proposed using electrons from a cold cathode to measure magnetic fields. Deflected by the Lorentz force, field-emitted electrons could hit one of several anodes, depending on the magnitude of the field.

This Miniaturized Triode (left) has an anode-to-grid distance of about 200 μm and the grid-to-cathode distance is about 20 μm. The hinges used in the pop-up fabrication are visible at the base of both the grid and the cathode. Shown above is the array of carbon nanotube emitters. Each emitter is 8 μm long and 10 nm in diameter.

(Courtesy of Wei Zhu, Agere Systems.)

References

1. C. Bower et al., Appl. Phys. Lett. 80, 3820 (2002).https://doi.org/10.1063/1.1480884

2. R. H. Fowler, L. W. Nordheim, Proc. R. Soc. London A119, 173 (1928).

3. W. A. de Heer, A. Châtelain, D. Ugarte, Science 270, 1179 (1995).https://doi.org/10.1126/science.270.5239.1179

4. C. Bower et al.,Appl. Phys. Lett. 77, 830 (2000); C. Bower et al., Appl. Phys. Lett. 77, 2767 (2000).https://doi.org/10.1063/1.1306658