A hybrid surface controls where frost forms

DOI: 10.1063/pt.ucfe.ubft

Frost tends not to form on the concave parts of leaves. Researchers have now replicated the geometry to manufacture a similar effect. (Photo by iStock.com/Anita Nicholson.)

An ephemeral layer of frost is a familiar sight for many of us on winter mornings. That frost doesn’t form evenly on leaves: The concave veins often don’t develop frost at all. In 2020, Kyoo-Chul Kenneth Park (Northwestern University

Frost forms in cold, humid environments when water vapor in the air condenses onto a surface and creates liquid drops that then freeze into porous ice. Under harsh frosting conditions, the process usually occurs within 10 minutes. Research efforts to prevent frost tend to focus on either creating a hygroscopic surface to absorb the moisture that would eventually freeze or designing a textured surface that concentrates the frost in specific regions. But not all the techniques are easily scalable, and nearly all lose their efficacy when scratched or contaminated by air particulates.

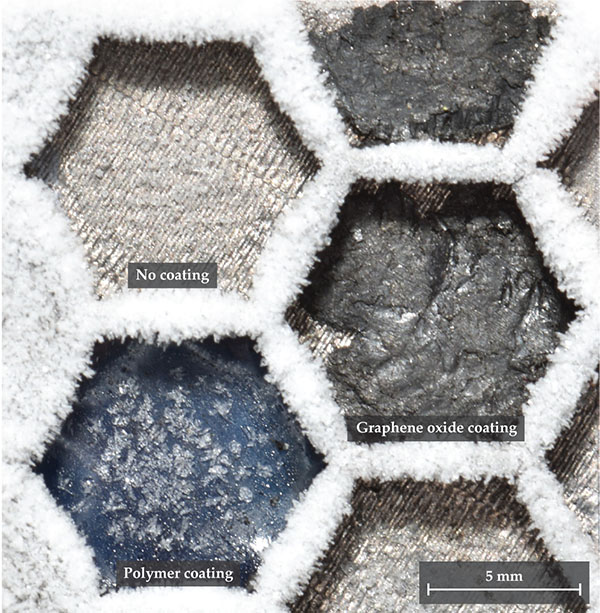

The flat region of a honeycomb surface texture (surrounded by 3-mm-tall walls) is less likely to form frost. After three hours, ice started to form on both the uncoated regions and those coated with a polymer. The region coated with graphene oxide remained frost-free for a week. (Image adapted from C. Machado et al., Sci. Adv. 10, eadq8525, 2024.)

Park’s group took a hybrid approach that combines a textured surface inspired by nature with a hygroscopic coating. The team’s previous research had shown that convex regions of a surface are frosted more often than flat regions because water-vapor molecules are more likely to bump into the peaks and change to a liquid. Using a 3D printer, the researchers produced either polymer or aluminum walls with a honeycomb structure, on which frost will more naturally form. Like it does in the concave regions of a leaf, frost is slower to form in the flat regions of the textured surface.

A coating of graphene oxide on a surface already delays the onset of frost; frosting is even further delayed when confined by a macrotexture. The test surface was enclosed in an environmental chamber, set to high-humidity conditions and cooled to freezing temperatures, and it took a week for frost to form on the coated, flat regions surrounded by the 3 mm honeycomb walls. Unlike previous surface coatings, graphene oxide is resistant to scratches. Its nanoscale interstitial spaces confine adsorbed water molecules and prevent frost formation.

Park and colleagues are working on scaling the technique. The honeycomb structure is not restricted to a certain material, and the graphene oxide coating can be easily deposited. The group is already performing more tests to better understand how the design would work in real environments. Many industrial applications don’t need materials to be 100% frost-free. In the future, a hybrid design may be used to reduce drag on airplane wings and to prevent power lines from collapsing under the weight of heavy frost accumulation. (C. Machado et al., Sci. Adv. 10, eadq8525, 2024

This article was originally published online on 22 November 2024.