New center aims to move electric vehicles that extra mile

DOI: 10.1063/PT.3.2008

In the 10 years since General Motors discontinued its unprofitable electric vehicle, EV1—the victim in the 2006 documentary Who Killed the Electric Car?—a new generation of plug-in hybrid and all-electric vehicles (AEVs) has emerged. Most of the new EVs are powered by lithium-ion batteries, which have double the energy density (typically expressed as kilowatt hours per unit mass) of the EV1’s nickel metal hydride (NiMH) battery (see the article by Héctor D. Abruña, Yasuyuki Kiya, and Jay C. Henderson in Physics Today, December 2008, page 43

Still, modern EVs face big hurdles: At current production levels, Li-ion transportation batteries are expensive, and their energy densities are insufficient for long-distance trips. As a result, US sales of modern EVs—fewer than 100 000 since 2010—have failed to keep the pace needed to meet President Obama’s 2008 goal to put one million electric cars on the road by 2015.

The next generation of EVs may fare better in the marketplace if a new consortium backed by the US Department of Energy achieves its ambitious goal of developing, within five years, a battery prototype that has five times the energy density and one-fifth the cost of the best commercially available options. Scientists in the Joint Center for Energy Storage Research (JCESR), hailing from five research universities, five federal labs, and four private companies, are forgoing the conventional Li-ion and NiMH electrochemistries and are exploring the fundamental chemistry and physics of batteries across multiple length scales.

“The last decade has produced dramatic advances in nanoscience, allowing us to observe, model, and control battery materials and phenomena at the atomic and molecular scale for the first time,” says JCESR director George Crabtree, a condensed-matter physicist at Argonne National Laboratory, where JCESR is based. “The opportunity-space beyond lithium-ion is much bigger than the lithium-ion space, where 90% of [today’s] battery research is done.”

Launched in November 2012, JCESR is one of five DOE energy innovation hubs that will receive $120 million over five years (see the

Range anxiety

Europe and Asia are pushing advanced vehicle-battery research for the same reasons as the US: to reduce greenhouse gas emissions and foreign oil imports. However, the US is also “looking to play catch-up with Asia” when it comes to battery manufacturing, says Steven Clark, senior manager for energy-storage technologies at Chrysler. Clark represents Chrysler on the management committee for the United States Advanced Battery Consortium, whose members are Chrysler, Ford, and General Motors. He says if the R&D pursued at JCESR and other US research institutions takes off, that could translate into a manufacturing advantage for the US.

Two decades after the commercialization of Li-ion batteries, “electrified transportation has reached a point of no return,” says chemist Michael Thackeray, whose research at Argonne has led to Li-ion technologies that have been patented and licensed for commercial use. One beneficiary of that research is the Chevy Volt, a plug-in hybrid electric vehicle that runs on a Li-ion battery until it falls below a predefined charge threshold, at which point the internal combustion engine kicks in to power an electric generator. The AEVs, which contain no engine or liquid fuels, include the Nissan Leaf, Tesla Model S, and Fiat 500e. The electric driving ranges of plug-in hybrids and AEVs correlate with the battery’s energy-storage capacity: For example, the Environmental Protection Agency rates the driving range of the Leaf’s 24-kWh battery at 117 km (72 miles) and Tesla’s 85-kWh Model S battery at 426 km.

Achieving electric driving ranges above 100 km can come with a stiff price. The battery systems in EVs can take up to 8 hours to recharge, can hog up to a quarter of the vehicle’s weight and volume, and are costly, with wholesale prices around $400/kWh. For a 40-kWh battery, that’s more than the price of an entry-level sedan with an internal combustion engine—Tesla’s 85-kWh Model S, for example, retails for $80 000. There’s only a niche market for a car like that, says retired atomic physicist Fred Schlachter, who coauthored a 2008 American Physical Society report on energy efficiency. “You reach a logical limit where the cabin is too cramped, the vehicle is too expensive, and the range is too small, to replace the family Camry.”

For AEVs, “you have to solve the range anxiety problem,” says Venkat Srinivasan, a deputy director at JCESR and a staff scientist at hub partner Lawrence Berkeley National Laboratory. In their quest to quintuple energy density and thus extend the driving range, JCESR researchers will draw from their combined expertise in electrochemistry, solid-state physics, materials synthesis and characterization, molecular simulation, and economic modeling to develop advanced battery prototypes. Hub partner Sandia National Laboratories will conduct wear-and-tear integrity and safety testing of the prototypes.

One long-standing technical challenge that JCESR is looking to solve is the development of a Li-air battery. In a Li-ion cell, the electrochemical reaction typically requires lithium, heavy metals, and oxygen. In proposed schemes for a Li-air cell, the principal reactants would be lithium metal and the unlimited, external supply of atmospheric oxygen gas. The elimination of reactants from the battery system is expected to significantly decrease its mass and lead to an energy density much higher than Li-ion.

Several efforts are under way to develop Li-air technology; for example, IBM’s Battery 500 project is aiming for a battery with a 500-mile (800-km) driving range. But after nearly two decades of research, several still unanswered scientific questions have dampened enthusiasm for a commercial Li-air battery. “Li-O2 has real scientific challenges,” says Stanley Whittingham, director of the Northeastern Center for Chemical Energy Storage at Stony Brook University. “There is presently no viable anode, electrolyte, or cathode. And I say Li-O2, not Li-air, because H2O, CO2 and N2 will all react with Li, so they must be removed.”

Electrochemical cells based on multivalent ions such as magnesium and zinc are also on JCESR’s agenda, although multivalent-ion research is still embryonic. The National Research Council report Transitions to Alternative Vehicles and Fuels, released in March, notes that advanced battery concepts “face serious technical challenges” but encourages continued funding for such R&D. New approaches are needed for a research field that has only made incremental advances in the past decade, says Abruña, director of the Energy Materials Center at Cornell University. “Following the path we’ve been on, it’s unlikely that we will get where we need to be.”

A galvanizing force

Whether JCESR succeeds or fails in meeting its ambitious five-year goal, Srinivasan says he expects the hub to become “a galvanizing force in battery science.” For example, JCESR held a battery science and characterization workshop at LBNL in May, after Physics Today went to press. Approximately 50 scientists were invited from the battery research and manufacturing communities, DOE’s x-ray and neutron-source user facility community, and the electron microscopy and NMR communities.

The JCESR hub joins a host of other DOE-funded programs that provide the technology push for the Obama administration’s longer-term “EV Everywhere” initiative to make EVs cost competitive with gasoline-powered vehicles by 2022. At the basic research end are DOE’s battery-related Energy Frontier Research Centers; at the applied end are high-risk battery R&D projects funded by the Advanced Research Projects Agency–Energy.

In his fiscal year 2014 budget (see the report

“The government is throwing a huge chunk of money at a big problem,” says University of Texas at Austin solid-state physicist John Goodenough, who received the 2011 National Medal of Science for his contributions to the development of the first commercial Li-ion batteries. “People are working hard, and I believe the problem is solvable,” Goodenough says, “but to get to the next stage, it’s going to take a little luck and some cleverness.”

US Department of Energy Energy Innovation Hubs (Lead Partner)

‣ Energy-Efficient Buildings Hub (Pennsylvania State University)

‣ Consortium for Advanced Simulation of Light Water Reactors (Oak Ridge National Laboratory)

‣ Joint Center for Artificial Photosynthesis (Caltech)

‣ Joint Center for Energy Storage Research (Argonne National Laboratory)

‣ Critical Materials Institute (Ames Laboratory)

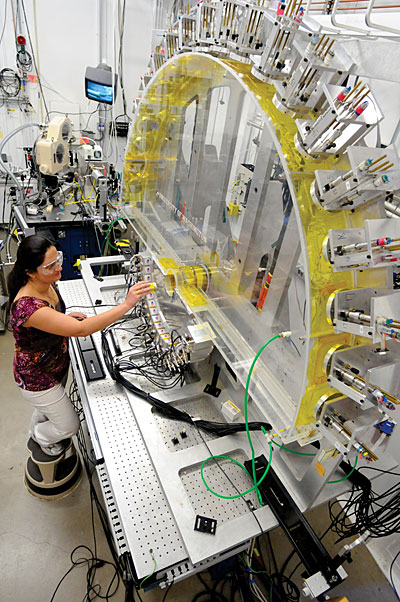

Materials scientist Swati V. Pol at Argonne National Laboratory loads a lithium-ion battery into a low-energy-resolution inelastic x-ray system at the lab’s Advanced Photon Source facility. Such multielement analytical tools will help researchers in the Joint Center for Energy Storage Research observe the material properties and processes that contribute to or limit battery performance.

ARGONNE NATIONAL LABORATORY