Lasers help categorize recyclables

A colorful assortment of plastic products.

iStock.com/narvikk

Do you dutifully recycle cardboard boxes, tin cans, and glass bottles? Perhaps they all go in the proper bin, and you feel good that you are generating less planet-polluting waste. But your part is only the beginning. For recycled items to be properly reused and introduced into the manufacturing process, detailed sorting procedures must happen in recycling facilities. Those processes are made more difficult by the inconsistency in people’s knowledge of what can and cannot be recycled. The amount of recycled material is only growing, and facilities need to be increasingly efficient to keep up with the quantity.

Automatic sorting methods help speed things up. Current facilities often have multiple optical separators that each identify and select a certain type of material. Those methods might be as simple as rotating sieves, which sort items by size, or giant magnets, which pick up the magnetic metals. More-sophisticated facilities use optical imaging or IR spectroscopy to identify specific types of materials, such as polypropylene plastics (the typical material for a screw-top bottle).

Those methods have their own limitations. Image-based methods can be confused by an item’s geometry, its color, or even by how it’s lit. IR spectroscopy is better, but sensors can be fooled by surface stains, requiring recycling facilities to use extra time and resources to clean the items first.

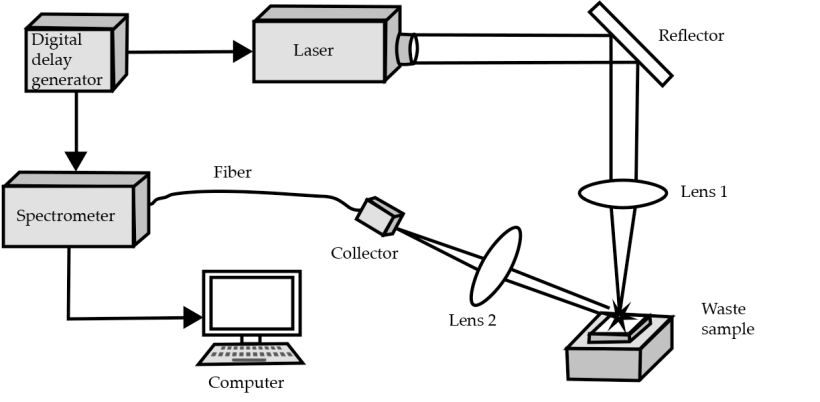

Laser-induced breakdown spectroscopy works by firing a laser at a sample to excite the atoms. The atoms then de-excite and emit light, which is captured and processed as a spectrum. A sample’s material can be deduced from its elemental composition.

Adapted from L. Yang et al., AIP Adv. 13, 075024 (2023)

Lei Yang and colleagues at Hefei University of Technology in China have proposed a new method of waste sorting that employs laser-induced breakdown spectroscopy (LIBS) in conjunction with machine-learning algorithms. LIBS uses a laser to rapidly excite and de-excite atoms in the target material, creating a plasma. A collector then detects the elemental composition of the material on the basis of its emission spectra (as seen in the diagram above). It is not influenced by ambient light, the cleanliness of the material, or the item’s visual properties. Basic, handheld LIBS systems are already in use to identify metal alloys. Incorporating LIBS and machine-learning techniques into recycling facilities could allow them to more efficiently handle the waste we produce, putting it back into the manufacturing process and creating a true closed-loop system.

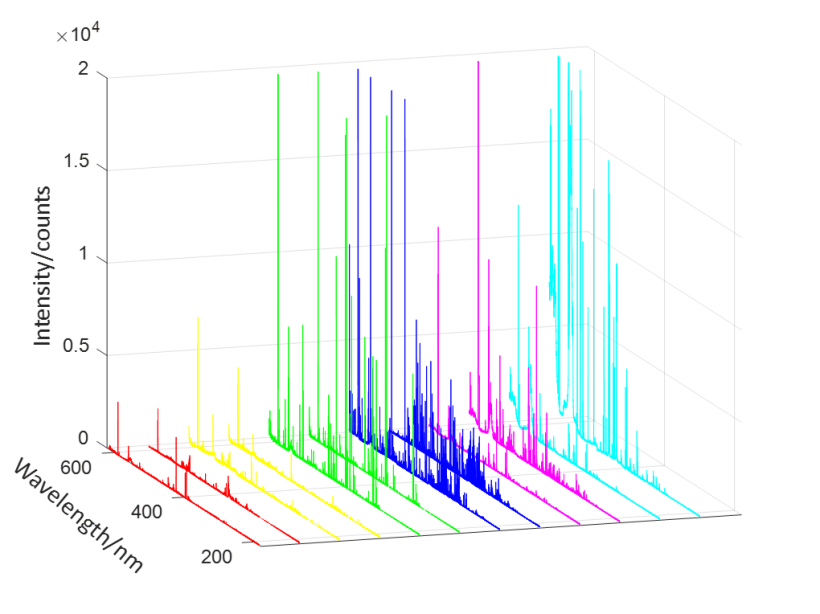

The system isn’t lightning fast, but it accomplishes a lot. A laser first strikes the material until the collected spectra are consistent; that cleaning of the sample ensures it is only measuring the material of the bulk object. Then 100 single-shot spectra are collected at different locations on the object (as seen in the spectrum below). The researchers used a bootstrap averaging method to create 50 low signal-to-noise spectra for use in the next stage of the analysis. In the study, they used different combinations of machine-learning algorithms to sort the materials into six categories: paper, plastic, glass, metal, textile, and wood.

The spectrum of a textbook contains many emission lines, including ones from carbon, sulfur, and oxygen. The spectrum is used to identify the primary material in a sample so that it can be processed correctly.

Lei Yang

LIBS identifies those six categories, plus multiple subcategories, all at once. The quality of the averaged spectra makes the biggest difference. In tests, existing sorting methods in conjunction with different machine-learning algorithms rarely achieved greater than 95% accuracy. Using LIBS, in conjunction with machine-learning techniques, materials were sorted into the six primary categories with 100% accuracy. Given the complexity of waste, there is still more to research before the method is installed in recycling facilities. (L. Yang et al., AIP Adv. 13, 075024, 2023