Jet-powered microscaffolds for tissue growth

DOI: 10.1063/1.2784674

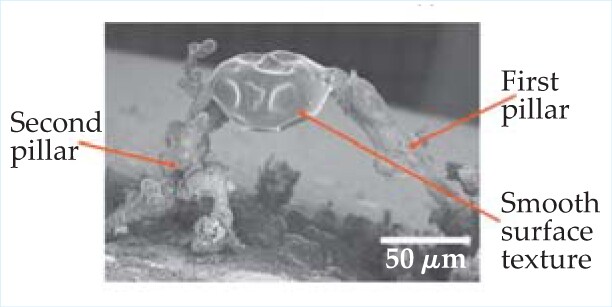

In some biological applications, cells need to be “seeded” into an artificial structure that provides mechanical support while allowing the cells to grow and function in their own microenvironment. Often, scaffolds are made using lithographic techniques on polymeric materials, but the required instrumentation is expensive. In recent years ink-jet printing has been used; the ink-jet droplets are usually 100 μm across or larger, making architectures smaller than that difficult to fabricate. Now Suwan Jayasinghe (University College London) and Alice Sullivan (Queen Mary, University of London) have found bioscaffolds to be a surprising application of the industrial electrospraying technique. In ES, the chemical or material of interest is suspended in a solvent and the solution is drawn out of a needle by a strong electric field. While being accelerated toward an electrode, the drops shrink and fission as the solvent evaporates. ES is used not only to paint metal surfaces but also as a workhorse of mass spectrometry wherein the material of interest becomes ionized as the drops evaporate. Jayasinghe and Sullivan used their own formulation of a siloxane-based colloidal suspension and found that in a small window of applied voltage and flow rate, a nearly mono distribution of nanoscale droplets could be generated, from 50 nm to 1 μm across depending on the parameters’ values. Using a point-shaped target electrode held beneath a glass slide and in line with the jetting needle, the researchers could grow a pillar of siloxane residue in 300 seconds. They made a second pillar and connected it to the first by slowly moving the jetting needle, then grew another structure at the top of the arch, creating the fully three-dimensional architecture seen here. Finally, by growing smooth-muscle cells on it, they showed their polymeric microstructure to be biocompatible. (A. C. Sullivan, S. N. Jayasinghe, Biomicrofluidics 1 , 034103, 2007 .)