Glass ages in material time

DOI: 10.1063/PT.3.4995

Follow a tour guide around a European city and you’re likely to hear the tale that old cathedral windowpanes appear uneven because over hundreds of years, the glass has slowly flowed toward the bottom of the pane. That story is just a myth; such flow in silica would require at least geological time scales. 1 But glassy materials, molecular and otherwise, do slowly evolve toward a metastable equilibrium state—a process known as aging.

Physical aging involves rearrangements in the atoms, molecules, or colloidal particles that make up a glassy material. Such materials are characterized by a glass-transition temperature

In 1971 Onbathiveli Narayanaswamy postulated that when exposed to sufficiently small perturbations, a material’s response will be in the linear regime.

2

He also asserted that a glass’s nonlinear properties could be extracted from that linear relationship by replacing the regular lab time with a so-called material time: a nonuniformly stretched time that reflects a material’s evolving state. The lab time

Although the material-time formalism has since been widely and successfully used to describe glass aging, it has never been directly tested. Without experiments sufficiently precise to reach the linear regime, extensions to the nonlinear regime have relied on assumptions about, rather than measurements of, linear behavior.

Now Birte Riechers and her coworkers at Roskilde University in Denmark have observed both the linear and nonlinear regimes in a glass-forming molecular liquid. 4 After performing a series of careful measurements to establish the material’s response to small changes in temperature, they were able to accurately, and with no adjustable parameters, predict its nonlinear behavior after larger temperature jumps.

Slow motion

The time it takes for a glassy system to find an equilibrium configuration is extremely temperature dependent. Just a 1% change in temperature can increase the time frame by a factor of 10. The slowing is caused not by a lack of thermal energy but by the particles trapping each other and preventing rearrangements toward an equilibrium configuration. Such traps might look like cages formed by surrounding molecules or like complicated tangles of polymers. The slowness causes a mismatch: The material’s temperature can change rather quickly, but its configuration can’t.

“This work started a bit as an experimental challenge to ourselves,” says Kristine Niss, who, with coauthor Tina Hecksher, led the experimental side of the project. Riechers and her fellow postdoc Lisa Roed wanted to see how small they could make the temperature jumps and whether they could, in fact, observe the linear regime, which required tiny temperature jumps of tens of millikelvin.

Niss’s group studies liquids whose small molecules form amorphous solids, rather than crystals, below

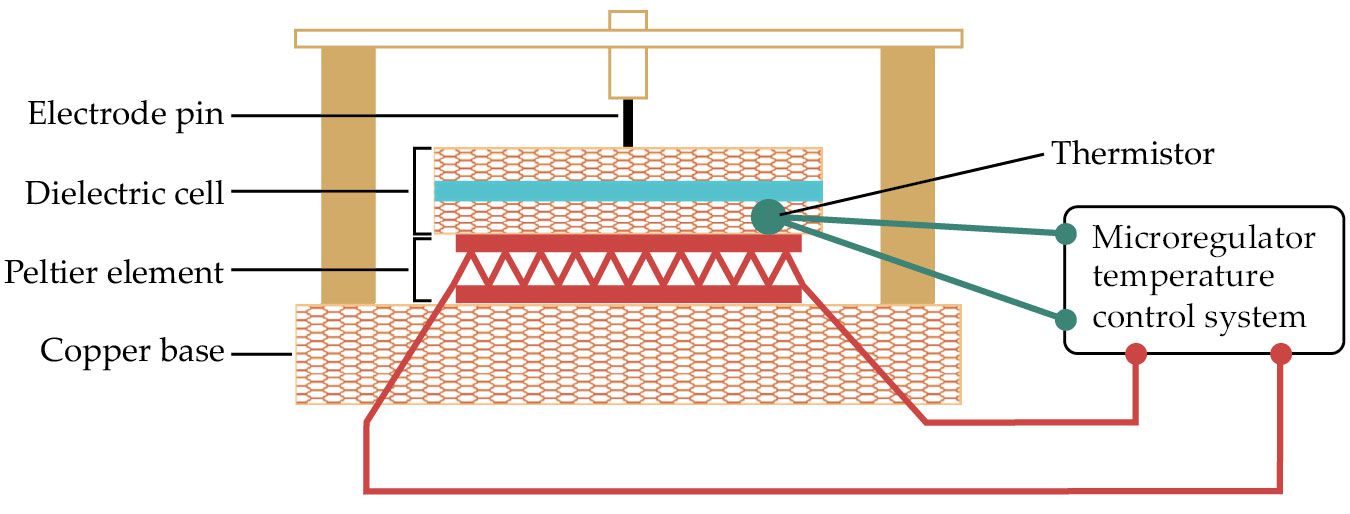

To get a sufficiently high signal-to-noise ratio from their existing experimental setup, shown schematically in figure

Figure 1.

A molecular liquid (turquoise) undergoes structural relaxation, known as aging, after being subjected to small temperature changes. The evolution of the 50-μm-thick layer’s capacitance refl ects changes in its microscopic confi guration. An electrode and dielectric cell measure the liquid’s capacitance; a thermistor and a Peltier element monitor and regulate its temperature. (Adapted from ref.

The entire experiment took a year to complete. The researchers had an existing setup, but they had to decide the new project was important enough to commit the apparatus to a single experiment for that long. The measurement ran uninterrupted during Denmark’s coronavirus lockdown, with Riechers coming in approximately once a week to check on it and make any necessary modifications.

During the first 36 weeks, the researchers subjected a thin sample of the liquid to temperature steps around a reference temperature of 164.6 K. At that temperature, the sample takes about 12 hours to relax to structural equilibrium— sufficiently long that the sample reaches a homogeneous temperature before any significant structural relaxation has taken place.

The step sizes varied from 10 mK to 3 K and went both up and down. After each jump, the sample’s configuration was allowed to equilibrate, which could take days or even weeks. During that time the researchers measured its capacitance at 10 kHz. A Peltier element kept temperature fluctuations to less than a millikelvin, and an ultraprecise capacitance bridge enabled resolution at the level of a few attofarad.

Those capacitance measurements yielded two important pieces of information. One was the linear response function

The other output was the material’s temperature-dependent aging rates. For a given thermal protocol, those can be used to nonlinearly transform the lab time into a material time. The new time scale, which reflects on the system’s configurational evolution, can be thought of as akin to the proper time in an accelerating relativistic system.

Predictable aging

The idea to push beyond linear aging, which was the project’s original target, and probe the nonlinear regime came from discussions with Jeppe Dyre, who led the theoretical side of the project. The last 15 weeks of data acquisition were dedicated to more complicated temperature-change protocols and probing the nonlinear regime.

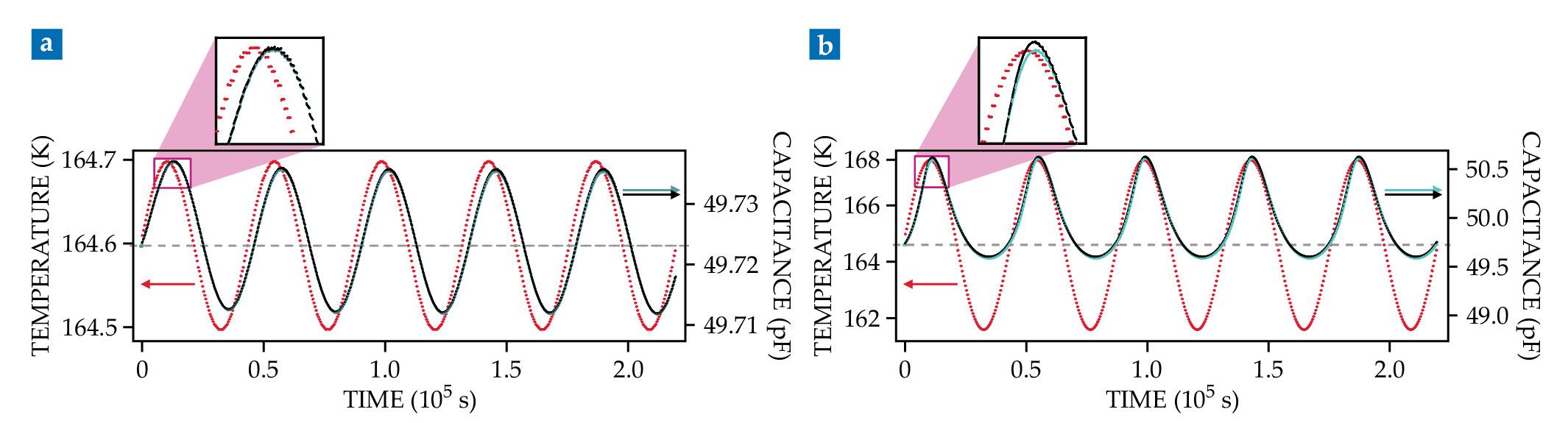

Figure

Figure 2.

Glassy materials age in response to temperature changes. (a) When a molecular liquid is subjected to a sinusoidal temperature protocol (red) with a sufficiently small amplitude, its capacitance (green) varies proportionally and closely matches theoretical predictions (black). (b) A larger-amplitude temperature change produces a nonlinear response if the liquid is close to its glass-transition temperature. When the linear-regime measurements are used to rescale the material’s response function, however, the nonlinear behavior can still be accurately predicted. (Adapted from ref.

The larger-amplitude temperature oscillation in figure

The ability to extend linear-response properties to the nonlinear regime can be explained if the same relaxation mechanisms are at work, which is plausible for a material that isn’t pushed too far out of equilibrium. The researchers support that understanding with simulations showing that by using the fluctuation– dissipation theorem with equilibrium fluctuations, they could predict the glass’s nonlinear aging. In the future they hope to demonstrate that connection in experiments.

But for larger temperature jumps of around 2.5 K, the researchers’ ability to predict

Still lacking is a microscopic picture of what exactly material time is and why it can bridge linear and nonlinear behavior. Dyre and his postdoc Ian Douglass propose that it could reflect how fast the slowest particles in an aging glass are moving. But exactly which aspects of the structure are involved, and how, is still part of the mystery of material time.

Another open question is how far the material-time formalism extends. Although the data already indicate a breakdown after sufficiently large temperature jumps, exactly why the theory breaks down is unclear. Niss and Dyre are also looking to extend their aging studies to glasses formed through other means, such as compression or shear, and to nonlinear responses to large electric fields.

References

1. E. D. Zanotto, Am. J. Phys. 66, 392 (1998). https://doi.org/10.1119/1.19026

2. O. S. Narayanaswamy, J. Am. Ceram. Soc. 54, 491 (1971). https://doi.org/10.1111/j.1151-2916.1971.tb12186.x

3. T. Hecksher et al., J. Chem. Phys. 142, 241103 (2015). https://doi.org/10.1063/1.4923000

4. B. Riechers et al., Sci. Adv. 8, eabl9809 (2022). https://doi.org/10.1126/sciadv.abl9809