Germany’s high-tech success due to (gasp!) government

DOI: 10.1063/PT.3.1358

Germany has emerged from the great recession as one of the world’s strongest economies,in large part because of successful government–industry targeting of applied research. In the US, such combinations are generally seen as undesirable interference in free markets or as picking winners and losers. The contrasting models were discussed at a Washington, DC, panel sponsored by the German embassy and the DC-based Information Technology and Innovation Foundation (ITIF) on 18 October.

“Germany has figured out something over the last decade about how to succeed in a worldwide economy that we haven’t [done],” said ITIF president Robert Atkinson. “The simple message [to US policymakers] is [to] support applied research cooperation between industry and government.”

Germany’s gross domestic product (GDP) has grown at an annualized average quarterly rate of 3.6% from January 2010 through June 2011, according to the Organisation for Economic Co-operation and Development (OECD). That compares with average quarterly growth of 2.6% in the US during that time. And while Department of Labor data show that the US shed 43% of its manufacturing workforce from 1997 through 2010, German factories lost only 8% of their laborers in that period.

The key to German economic health has been its deliberate drive to expand the proportion of its GDP that consists of high-tech goods. Germany now produces seven times more of its GDP from research-intensive goods and services than does the US, noted Atkinson and other forum presenters. And Germany’s success has come with a manufacturing wage that is nearly 40% higher, and a corporate tax rate 12% higher, than the US’s.

A planned system

“Germany has a highly pragmatic, consensus-based, collaborative innovation policy,” said Stephen Ezell, a senior analyst at ITIF. “The government is unabashed about identifying key technologies and organizing society toward its goals.” A high-tech strategy adopted by the German government in 2006 and reconfirmed by that nation’s cabinet in 2010 targets five broad topical areas for R&D: clean energy, health and nutrition, mobility, security, and communications technologies. The development of clean energy technologies has become more urgent as a result of the government’s decision earlier this year to phase out nuclear energy in Germany over 15 years, said Engelbert Beyer, head of innovation strategies at the Federal Ministry of Education and Research. The German model has shown that companies that compete fiercely with each other in the marketplace can collaborate on technologies that require further development before they are market-ready, Beyer said.

In Germany, much of the precompetitive research occurs in such nonprofit institutes as the Max Planck Society and the Leibniz Association, each of which operates dozens of individual R&D centers. With 60 institutes located in Germany, the Fraunhofer Society is one of the largest applied-research performers in Europe. Through a decades-old arrangement, the federal government matches industry contributions one-for-one, said Anke Hellwig, Fraunhofer’s deputy director of international business development. In 2010, industry supplied €463 million ($741 million), roughly one-third of Fraunhofer’s €1.6 billion in revenues for the year. The federal government supplied another €362 million in institutional funding to Fraunhofer last year for R&D on national needs such as low-loss electricity generation and distribution, recycling of materials, low-emission transportation, and disaster prediction and management. Additional funding is provided by state governments.

US a “black box”

In contrast to the planned model seen in Germany, the US innovation system resembles a “black box model, where the government basically funds science, then steps aside and expects market forces to do all the rest,” said Gregory Tassey, senior economist at NIST. The US approach, he argued, rules out “a whole range of conceivable policy instruments that are at the disposal of any government.” Rare exceptions to that model include the SEMATECH consortium, in which the US government provided $500 million over five years, beginning in 1988, to help save US semiconductor manufacturers from near collapse.

Once the most research-intensive economy in the world, the US was ranked seventh among developed nations in 2008, when the OECD made its most recent comparison. The country has since likely slipped to ninth place, Tassey said, behind Taiwan and Singapore.

President Obama has recognized the need to improve manufacturing competitiveness. His Advanced Manufacturing Partnership plan calls for about $500 million annually in federal support for collaborations among government, universities, and industry (see PHYSICS TODAY,August 2011, page 27

In a presidential memorandum issued 28 October, Obama directed all agencies operating laboratories to redouble their efforts to move their inventions into the marketplace. The memo instructs the agencies to streamline their licensing, cooperative R&D, and other technology-transfer mechanisms, and to draw up five-year plans setting forth explicit goals for numbers of licenses, cooperative agreements, spinoffs, or other quantitative metrics of their technology commercialization performances.

High-leverage program

In a related move, Obama announced in September the launch of a new searchable Web-based resource to put manufacturers, tech firms, and entrepreneurs in touch with public–private organizations and initiatives designed to assist them. The site, which at press time had yet to debut, is to provide information on 900 organizations that offer capital, entrepreneurial support, and technical assistance. That will add to an existing resource for US manufacturers: NIST’s Manufacturing Extension Partnership (MEP), which offers small companies help from a network of 1400 affiliated consultants on how to improve productivity, through steps such as reducing work in process (semifinished products), improving on-time delivery, and reducing lead times.

A NIST report published in February identified $32 in economic growth for every $1 in federal spending on the MEP. Surveys of the MEP’s clients indicate the program has created or retained one job for every $1570 in federal funding spent, said Tassey. But funding for the 20-year-old MEP has been declining in real terms. Appropriations for this year have yet to be finalized, but the Senate appears set to cut $8 million from last year’s $128.4 million level. The House spending plan would keep the MEP’s funding even with the 2011 level.

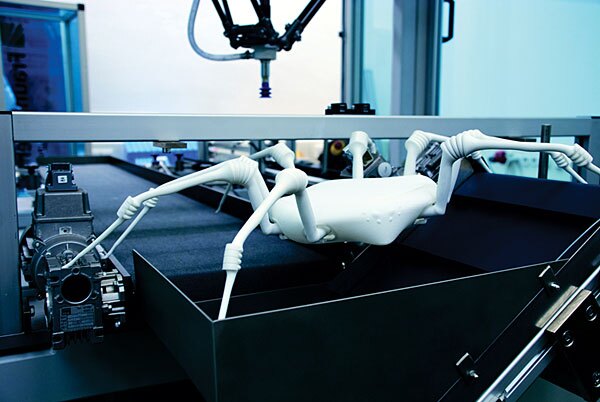

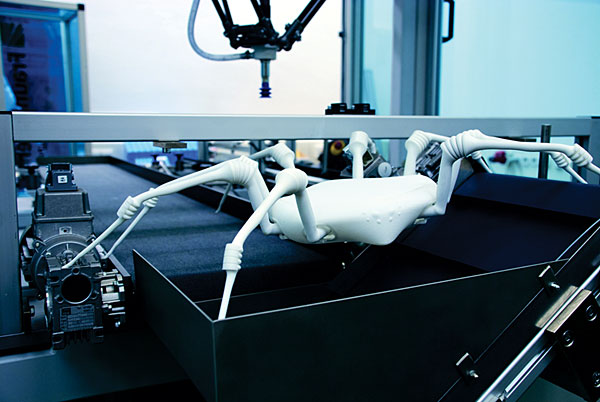

A prototype mechanical spider developed by the Fraunhofer Institute for Manufacturing Engineering and Automation could crawl into places too hazardous for humans.

Fraunhofer IPA

More about the authors

David Kramer, dkramer@aip.org