After Serious Accident, SLAC Experiments Remain Shut Down and DOE Report Faults Lab’s Safety Oversight

DOI: 10.1063/1.1897516

All the accelerators and storage rings at SLAC have been shut down since 11 October, when an electrical accident at the laboratory severely injured an electrician working for a subcontractor. SLAC director Jonathan Dorfan ordered the shutdown immediately after the accident, and he has decided that all experimental facilities should remain closed pending the findings of a Department of Energy accident-investigation board and implementation of the remedies it mandates.

SLAC is funded by DOE. The investigation board, headed by DOE’s Richard Stark, was charged with investigating the proximate and root causes of the accident.

The board’s report was released on 15 December. (It can be requested at http://www.eh.doe.gov/csa/reports/accidents

The most visible competition in which SLAC is at present involved is the rivalry between the laboratory’s flagship BaBar experiment and the very similar Belle experiment at the KEK laboratory in Tsukuba, Japan (see Physics Today, May 2001, page 17

BaBar and Belle both began taking data in 1999, fall behind its rival in the accumulation of data. The accident report suggests that SLAC has been cutting safety corners in the pursuit of maximal data acquisition. “The significant breakdown in the enforcement of health and safety requirements is indicative of a work environment where occupational safety and health policies, programs, and procedures are not fully implemented,” says the report. “The [site engineering and maintenance department], in particular, has not balanced the priorities of accelerator operation and worker protection.”

The accident

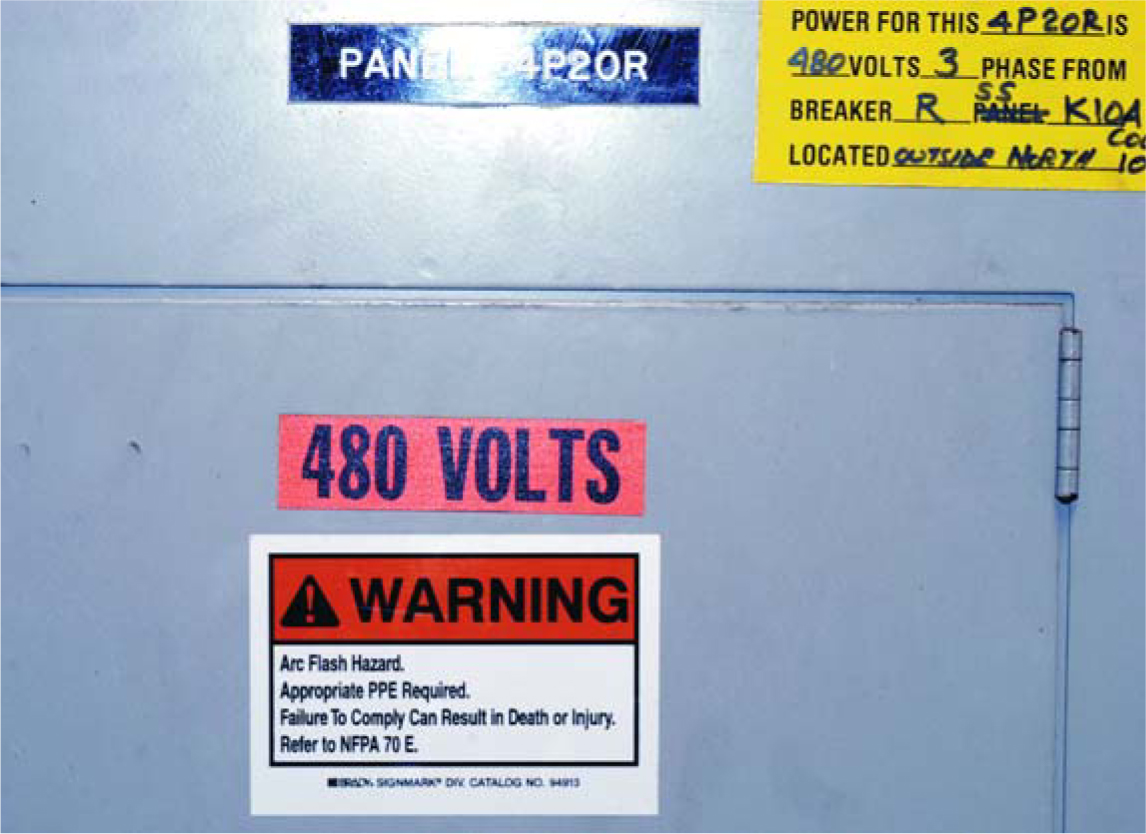

On the morning of 11 October, a SLAC field supervisor asked David Simon, an electrician employed by a local maintenance contractor, to install a circuit breaker for a ventilation fan in a 480-volt electrical panel in the linear accelerator’s klystron gallery (see the figure on page 25). The linac was running in preparation for the startup of the PEPII collider after a 15-week summer shutdown for routine maintenance, and the panel was energized. Such “hot work” is sometimes justified because it avoids the delays involved in shutting off electric power. But because it can be risky, SLAC safety rules mandate a special permit for each such task.

Cover of the electrical panel at which the 11 October accident occurred in the klystron gallery at SLAC. Despite its warning labels (PPE means personal protective equipment), the 480-volt panel was energized when the electrician was installing a circuit breaker, and he was not wearing fire-retardant clothing.

SLAC

As Simon was installing the circuit breaker in the energized panel, an arc flash ignited his clothing. He was wearing protective gloves, but not the appropriate fire-retardant clothing. The pressure burst from the arc also knocked down a fellow worker nearby. A third worker in the room attempted to smother the flames, but Simon suffered second- and third-degree burns over about half his body. The 51-year-old electrician was hospitalized for a month and is now recovering at his family home in West Virginia.

The investigation board found that there was no justification for installing the breaker while the panel was energized. In any case, no permit had been sought or issued for the hot work Simon was doing. The report calls the events leading up to the accident “characteristic of an unstructured and largely undocumented approach to work that does not ensure safety.” In fact, an internal safety review at SLAC earlier in 2004 had concluded that, of the 31 hot-work permits issued in the preceding three months, 23 did not have adequate justification. Nonetheless, the DOE report concludes, “SLAC management and [DOE’s Stanford Site Office] did not demonstrate a sense of urgency in implementing the recommendations that resulted from the [internal] review.”

What needs to be done

Accompanying the report’s conclusions are a dozen “judgments of need.” The report stresses that “the SLAC director needs to balance the priorities between operation and safety … and ensure that employees at all levels understand that concern for mission accomplishments not outweigh [safety].” More specifically, the report enjoins SLAC to enforce all applicable safety standards and to ensure that employees and outside contractors who work near energized conductors—and their supervisors—are trained in safe practices. The report contends that DOE’s Stanford Site Office needs to develop safety oversight programs and, when necessary, exercise its authority to stop work or embargo funds.

“The board did a very rigorous job of looking into the underlying causes of the accident,” says SLAC spokesman Neil Calder. “And we thank them for it. Our aims are the same, namely to make SLAC a completely safe place to work.” To implement the board’s recommendations, DOE has appointed a corrective-action committee of experts from SLAC and other labs, coordinated by George Malosh of Oak Ridge National Laboratory. The committee began work as soon as the accident report was released and is to report its progress by the middle of this month.

Because SLAC is also subject to Stanford University, which runs the laboratory for DOE, university president John Hennessy has appointed his own “blue ribbon panel” in the wake of the accident report. Charles Shank, former director of Lawrence Berkeley National Laboratory, is a member of the panel. “Although safety might have been lacking in some areas at SLAC,” says Shank, “Dorfan is well known among lab directors for his strong commitment to safety.”

The Stanford panel is asked to ensure that appropriate systems and procedures are in place for safe resumption of the SLAC experimental program. The panel is expected to report to Hennessy by 1 March. Final approval for restarting the accelerators and storage rings on the SLAC site, including the Stanford Synchrotron Radiation Laboratory’s standalone SPEAR ring, must come from DOE.