Biomimetic ceramics

DOI: 10.1063/1.3074273

Researchers are increasingly looking to nature’s broad collection of processes and materials for inspiration. Models for lightweight, high-performance structural materials, for instance, can be found in bone, dentin, and nacre, also known as mother-of-pearl; all demonstrate a combination of strength and toughness that thus far has eluded reproduction in the laboratory. But a team from Lawrence Berkeley National Laboratory has recently succeeded in incorporating many of the desirable characteristics of nacre into a composite ceramic.

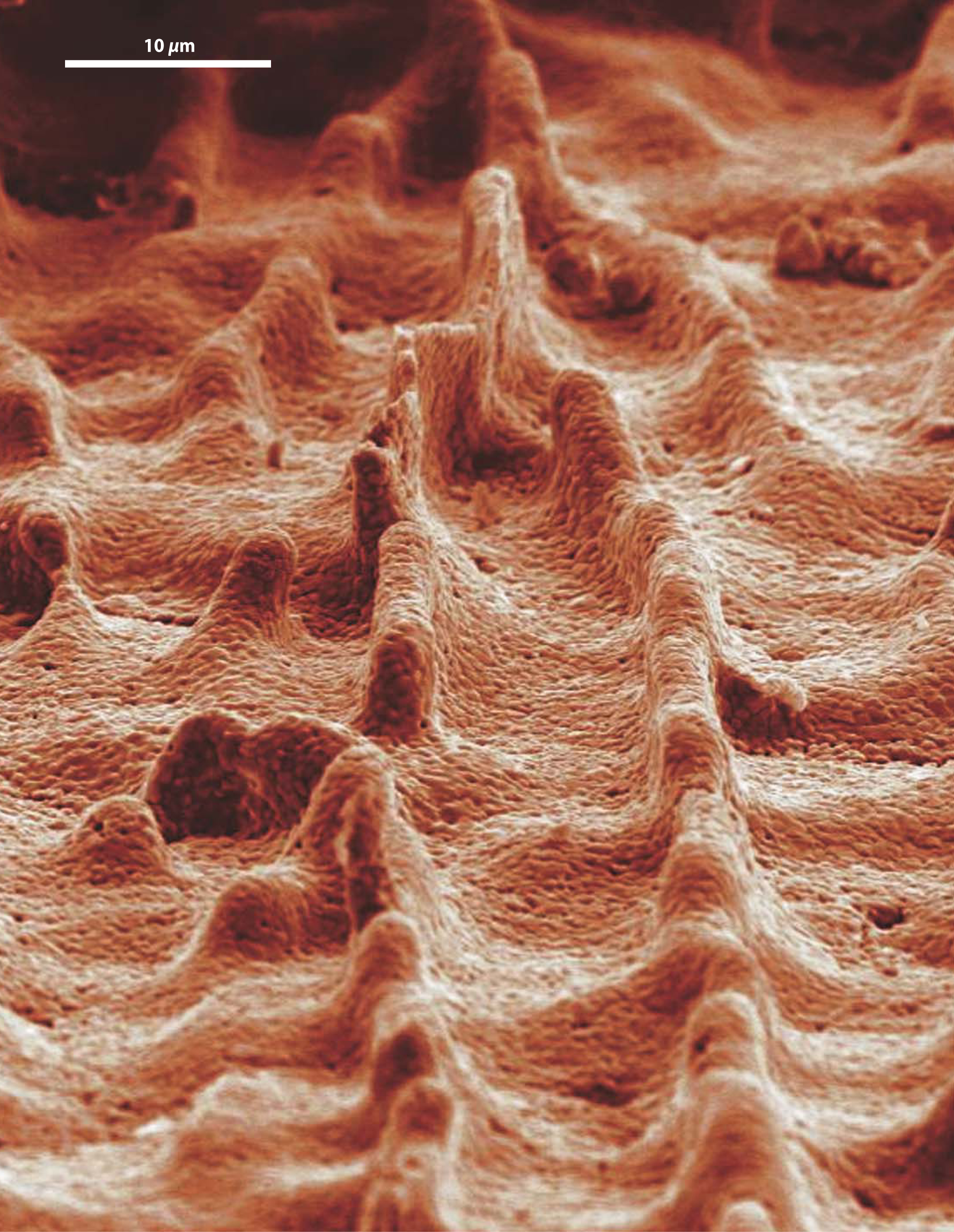

Nacre consists of platelets of the mineral aragonite (CaCO3) bonded together by thin layers of organic material in an arrangement similar to bricks and mortar. The platelets provide the strength, and the organic layers allow strain relief through interlayer shearing. Key to nacre’s toughness is its complex hierarchical structure, which spans length scales from nanometers to microns. The Berkeley ceramic mimics that structure. Shown here is one of the “bricks”: a crystal of aluminum oxide. Holding the bricks together in the ceramic is a lubricating “mortar” of the common polymer polymethyl methacrylate. To form the composite, the researchers freeze a solution of alumina in water, which yields a layered, scaffolding configuration; the water is later replaced by polymer and the ceramic is sintered to form the bricks. Adding sugar to the initial solution gives the bricks a rough topography, as seen here. Such microscopic roughness and the bridges that can form between bricks enhance the composite’s toughness. The resulting ceramic is 300 times tougher (in terms of fracture energy) than either constituent, and its specific strength and toughness properties are comparable to those of aluminum alloys. (E. Munch et al., Science 322 , 1516, 2008 http://dx.doi.org/10.1126/science.1164865

To submit candidate images for Back Scatter, visit http://www.physicstoday.org/backscatter.html

Image courtesy of DOE/Lawrence Berkeley National Laboratory.