Making archaeology cool with dry-ice cleaning

DOI: 10.1063/PT.3.3929

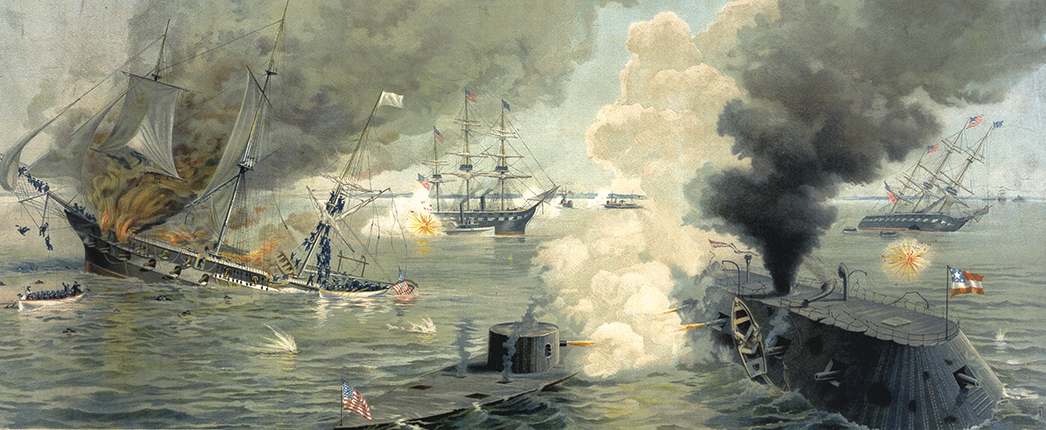

It was a clash that would change the course of naval warfare. During the American Civil War, the Union ship USS Monitor fought the Confederate ironclad CSS Virginia on 9 March 1862, the second day of the Battle of Hampton Roads in Virginia. The encounter was the first time that ironclad ships engaged in combat against each other. The two vessels pounded on each other for nearly four hours at less than 100 yards, but, amazingly, neither ship critically damaged the other. The outcome was much different from what the Confederate Navy had experienced the previous day, when its iron-armored ship destroyed or damaged several wooden Union ships. Although the encounter between the ironclads was ultimately a draw, the battle signaled the end of the wooden warship. It was clear: Iron is superior.

On 31 December 1862, the Monitor was caught in a storm and sank 16 nautical miles off the coast of Cape Hatteras, North Carolina, while en route to Beaufort, North Carolina. More than a century later, on 27 August 1973, an expedition using a towed sonar system discovered the Monitor resting upside down on the seafloor at a depth of 220 feet. Two years later the establishment of the Monitor National Marine Sanctuary brought the wreck site under the jurisdiction of NOAA.

Starting in 1998 archaeologists from NOAA, assisted by US Navy divers, began a large-scale recovery of the aft portion of the vessel. The effort began with the retrieval of much of the engine room and culminated in 2002 with the raising of the iconic 120-ton revolving gun turret. All the retrieved artifacts have undergone or are now undergoing conservation treatment in the Batten Conservation Laboratory Complex at the Mariners’ Museum and Park in Newport News, Virginia. The goal is to arrest the effects of mechanical and chemical degradation that occurred while the objects were buried, so that the materials can be used to tell the stories of the ship and its crew. If not treated, the artifacts will almost certainly continue to deteriorate and may be lost completely.

A conservation challenge

The task of conserving Monitor artifacts can be quite daunting, in part because of the variety of materials that make up the objects: wood, cast iron, wrought iron, brass, and bronze, all of which deteriorate differently. Most of the Monitor collection is wrought iron, including the hull plating, engine-room bulkheads, the propeller shaft, and, most significantly, the 9-foot-tall, 20-foot-diameter revolving gun turret. When those artifacts arrived at the museum, they were covered in thick layers of marine growth, sediment, and corrosion products. Much of that covering has been removed mechanically with hammers, chisels, and pneumatic tools. The surviving exposed metal structures revealed layered surfaces similar in appearance to waterlogged wood. Corrosion on wrought-iron objects from both land and marine sites predominantly develops along slag stringers, inclusions that are stretched out as the metal is worked and folded during the forging process. As a result, deep, linear, compact corrosion pockets are intermixed with the surviving metal structures.

Embedded within the corrosion material are chlorides from seawater that, if not removed, can lead to continued corrosion. On smaller artifacts, conservators often use various scalpels, dental tools, and pneumatic micro jackhammers to remove the corrosion material. The process can be laborious and time consuming, so when the time came to conduct similar cleaning regimes on the larger, more monumental artifacts such as the gun turret, it was evident that hand cleaning was impractical. The conservation staff began looking for an abrasive cleaning method that was effective in a relatively short period of time, was safe for staff and objects, and would result in minimal byproduct.

Dry-ice blasting fits the criteria. The air-powered cleaning method uses frozen carbon dioxide at −78.5 °C rather than other abrasive media such as sand or walnut shell. Unlike traditional blasting techniques, dry ice sublimates to gas, so the only residue left behind is material that was removed during the cleaning process. In addition, dry ice is noncorrosive, nonconductive, dry, and nontoxic, properties that make it ideal for numerous applications. Solid-dry-ice cleaning systems commonly consist of an air compressor connected to an air dryer connected to a controller unit, where dry-ice particles mix with air and are accelerated out through a hose and nozzle; the photo on the preceding

The keelson plate of the USS Monitor receives a dry-ice cleaning from conservator Mike Saul. The hose is attached to a controller, where dry ice and air are mixed. The controller is connected to a portable air dryer linked to a diesel-powered Doosan compressor. (Courtesy of the Mariners’ Museum and Park.)

Articles describing the mechanism for dry-ice cleaning often say it is based on three factors: thermal shock due to the cold dry-ice particles, gas-expansion pressure from the sublimation of the dry ice, and the impact of the dry-ice particles on the material to be removed. However, in his 2008 PhD thesis, Mark Claudius Krieg showed that the thermal and gas-expansion effects play only a minor role.

The mechanical impact of the dry-ice particles is the true driver of dry-ice cleaning, and greater impact means potentially greater ability to break up surface debris, coatings, and so forth. Impact, in turn, increases with faster, more massive particles hitting the surface straight on.

The speed of the dry-ice particles is primarily controlled by the air pressure supplied by the cleaning system, though the working distance is also important because the particles lose speed as they move away from the nozzle. The direction of the cleaning medium is determined by the nozzle’s shape and design and by how it is held during the cleaning procedure. The number of dry-ice particles in the system is determined by the rate at which dry ice is added to the airstream and the volume of airflow. To help control the aggressiveness of the cleaning action, a conservator can vary the particle size from large, 3-mm-diameter pellets down to the size and consistency of fine snow.

Best practices

When the conservation staff of the Mariners’ Museum and Park began to consider dry-ice cleaning technology, we found little in the literature describing its application for removing corrosion on archaeological wrought-iron objects. Therefore, we began a two-phase experiment to determine the feasibility of the method and evaluate the appropriateness of available systems. The first phase entailed visually identifying how effective a cleaning approach was in removing the embedded corrosion while leaving the surviving metal intact. Once we established that the corrosion could be removed with no observable damage to the metal surface, we moved on to the second phase, in which we analyzed surfaces before and after cleaning to ascertain if the cleaning process produced microstructure damage that was not visually apparent.

Once we had determined the best air pressure, pellet size, and so forth, we carried out a full-scale cleaning test on a roughly 3 ft × 8 ft wrought-iron keelson, a plate that provides structural reinforcement. During the test, we were able to remove almost all embedded corrosion products in approximately one hour; to achieve the same amount of cleaning by hand would have taken several weeks.

Since April 2016 the conservation department has begun (and in some cases completed) the dry-ice cleaning of 492 wrought-iron Monitor artifacts. Our goal is to conduct a major cleaning effort on the turret this summer. You are invited to view much of our work through glass windows that look into the Batten Conservation Laboratory Complex at the Mariners’ Museum and Park or via webcams at the museum’s website, www.marinersmuseum.org

The engagement between the ironclads USS Monitor (center foreground) and CSS Virginia (right) is brought to life in this 19th-century lithograph. Note the Monitor’s gun turret: Its use marked the first time a revolving turret had been employed on a ship. (Courtesy of the Mariners’ Museum and Park.)

References

► R. van der Molen et al., “Metal 2010: Proceedings of the Interim Meeting of the ICOM-CC Metal Working Group, P. Mardikian et al., eds., Clemson U. (2010), p. 135.

► C. Cutulle, S. Kim, “Objects Specialty Group Sessions Postprints, Volume Twenty-Two, 2015, E. Hamilton, K. Dodson, eds., American Institute for Conservation of Historic and Artistic Works (2016), p. 77.

More about the authors

Will Hoffman is the director of conservation and chief conservator at the Mariners’ Museum and Park in Newport News, Virginia.