Satellite repair and refueling demos may soon spur a new industry

DOI: 10.1063/PT.3.4066

When a satellite breaks down or reaches the end of its life, operators have two disposal options. They can direct it into a lower orbit, where it burns up in Earth’s atmosphere, sometimes producing remains that sink in the satellite graveyard of the remote southeastern Pacific Ocean. Or they can relocate an aging satellite to a less crowded, higher orbit. New technologies may soon offer a third alternative: repairing, refueling, and even upgrading satellites already in orbit.

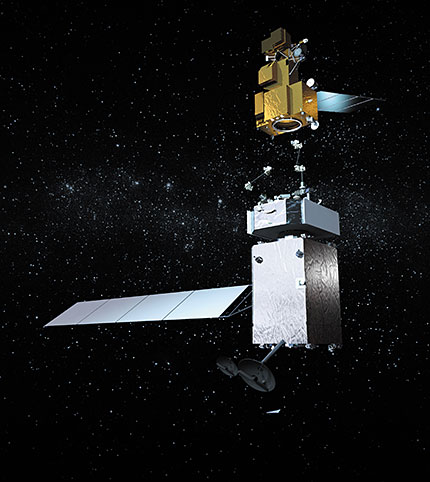

At NASA’s Goddard Space Flight Center, for example, scientists and engineers are working to extend the life of a currently operational government satellite. Their project, Restore-L, will use robotic arms to manipulate a set of tools to refuel the Landsat 7 satellite in low Earth orbit. A similar project, targeted for client satellites in geosynchronous orbit, is under way at the Defense Department. And Northrop Grumman is working on a vehicle for customized servicing of a geosynchronous communications satellite.

One of the first examples of in-orbit satellite servicing took place in 1973, when the Skylab crew replaced a sunshade and unjammed a solar panel damaged during launch. Then in April 1984, astronauts aboard the space shuttle Challenger repaired the attitude-control system of the Solar Maximum Mission. Servicing continued with the Hubble Space Telescope, which has been fixed and upgraded in orbit four times.

Some robotic in-orbit servicing operations have been demonstrated too. In 1997 the Japan Aerospace Exploration Agency successfully tested robotics and docking technology with a pair of satellites designed for servicing. The Defense Advanced Research Projects Agency (DARPA), with NASA’s help, completed a hardware-transfer demonstration in 2007. More recently, NASA and its partners successfully tested robotic refueling at the International Space Station in 2011–14. What’s different with Restore-L is that it will autonomously navigate to and robotically refuel an operational satellite not designed for in-orbit servicing.

NASA’s Restore-L mission will use autonomous navigation, robotic arms, and propellant-transfer technologies to refuel Landsat 7, a satellite that is in low Earth orbit and not designed for servicing. (Artist’s rendering courtesy of NASA.)

“We are doing many things for the first time in orbit,” says Brent Robertson, project manager for Restore-L. The aim is to showcase a combination of technologies: autonomous navigation, versatile robotic arms, and propellant transfer. Since mid 2016, NASA scientists and engineers, with contract support from California-based spacecraft manufacturer SSL, have been implementing those technologies to work seamlessly together so that Restore-L can service Landsat 7 in 2022.

NASA’s choice to demonstrate Restore-L’s capabilities on Landsat 7 was based partly on timing; the satellite is expected to be nearly out of fuel when Restore-L is scheduled to launch. In addition, Landsat 7 is “a fairly representative satellite,” says Robertson. The common design of the interface where the satellite was attached to the launch vehicle makes the technology generalizable to many other satellites.

Rendezvous and refuel

Making contact with Landsat 7 is the first challenge. The rendezvous is difficult in a low-gravity environment: Even a small bump could nudge the target satellite away. “Once we’re about a meter away, we will give a go-for-capture command,” says Robertson. At that point, an autonomous navigation system on Restore-L will kick in. The communications delay between the ground and low Earth orbit prevents human-guided navigation. When Restore-L is close enough, one of its two robotic arms will reach out and grasp the target.

After the satellite is captured, the procedure requires a robotic arm to manipulate tools. First, the arm will have to grab a cutting tool to remove a protective thermal blanket that reflects the Sun’s heat from Landsat 7. Then, having exposed the fuel tank’s fill and drain valves, the arm will use a different cutting tool to remove the wires that hold the valves. As one arm unscrews the fuel caps, the other will hold on to the caps so they don’t drift off. Finally, Restore-L will attach the refueling component to its robotic arm, open the fill valve, and transfer 100 kg of hydrazine (N2H4) fuel to Landsat 7. “You want to make sure you’re watching the thermal temperature in the fueling system,” says Robertson. “Things can heat up, and you want to stop and let things cool down. We won’t be in a hurry to get everything done.” The entire refueling operation is expected to take a few weeks. At the end, the robotic arm will attach a thermal enclosure over the valves and then use the gripper tool to unlatch from Landsat 7.

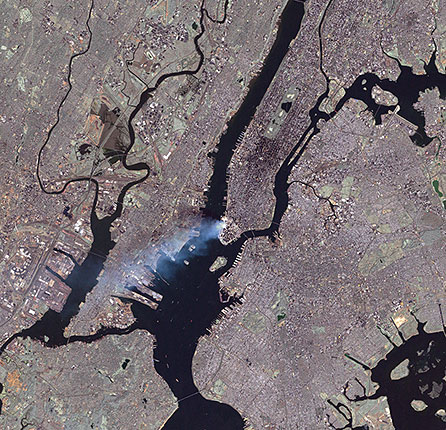

NASA anticipates the refueling effort will extend Landsat 7 operations by several years. More scientific data could be collected during that extra life. The satellite could also work with existing US Geological Survey data-collection efforts or serve as a calibration instrument for other government satellites.

Industry interest

The technologies developed for Restore-L will be transferred to the US satellite manufacturing industry to help offset R&D risk to businesses. While NASA has no plans for Restore-L after servicing Landsat 7, spacecraft manufacturer SSL, which is developing the robotic arms and the satellite bus, may have additional uses for Restore-L. Trudy Kortes, executive of NASA’s Technology Demonstration Missions program, says, “there’s a large market interest here.”

Others in the satellite-servicing field point out hurdles. “People have a natural urge to want to service and salvage a multihundred-million-dollar or billion-dollar spacecraft,” says Ian Fichtenbaum, director of Bradford Space, a European-based manufacturer of satellite components. “But if the repair truck you’re calling costs tens of millions to launch and hundreds of millions to build, that calculation gives you pause.” The total cost for the design, development, build, test, launch, and operation of Restore-L is estimated at just under a billion dollars. Whereas manufacturers could use the technologies to build a less expensive servicer in the future, he says, “the total cost of servicing is about the same as the cost of what you are servicing.”

But if a commercial instrument that brings in tens or hundreds of millions of dollars each year needs fuel or basic maintenance to continue its operation, a satellite owner may be willing to pay. A 2018 market analysis by Carolyn Belle of Northern Sky Research (NSR) shows that the total potential profit for satellite servicers “ranges in the hundreds of millions of dollars for this industry, perhaps $700 million by 2026–27.”

Richard Parker, cofounder of Maryland-based Assure Space, which provides space insurance to satellite operators, says he is not sure if there would be enough demand to support a servicing industry. “We do get satellite malfunctions but it’s once every two or three years,” he says. “I don’t quite believe the business model. These robotic satellites could be sitting around doing nothing.”

Dennis Wingo, CEO and founder of California-based Skycorp, says the economics of satellite servicing may need to change for the industry to grow. If operators extend the life of their servicing satellites, they can charge less per customer, he says. “That change will increase business, so there’s a virtuous circle that can develop. But the cost must come down due to the competitive pressures from terrestrial communications services.”

DARPA’s Robotic Servicing of Geosynchronous Satellites program aims to repair several commercial and government satellites. Its first attempt, the Robotic Servicing Vehicle (RSV), is slated to launch in 2021 to provide support that includes high-resolution inspection, refueling, repair, orbit relocation, and software upgrades. DARPA has teamed up with SSL for the project. “We are building the robotic arms and the spacecraft bus,” says Al Tadros, a vice president at SSL. “We’ll also operate the robotic servicing vehicle.”

As the name of its parent program suggests, the RSV will operate in the commercially rich geosynchronous orbit. According to Tadros, the RSV could service two dozen or more satellites during its lifetime. About 300 commercial and 80 government satellites are currently in geosynchronous orbit.

High-resolution image of the World Trade Center in New York City, captured by the Landsat 7 satellite on the morning of 11 September 2001. The Restore-L mission would refuel the satellite and extend its lifetime.

USGS LANDSAT 7 TEAM, AT THE EROS DATA CENTER

That’s where the money is, says Wingo. “The only satellites in low Earth orbit are government satellites and are often classified. They don’t want you near them.” Traveling from one satellite to another in low Earth orbit is expensive from an energy point of view, too, he says. A mission to service a satellite in low Earth orbit would need to make all its money from one client. In contrast, the energy needed to go from one geosynchronous satellite to the next is small enough that multiple clients could be served.

A new technology patented by Wingo underpins the Orbital ATK and Northrop Grumman Mission Extension Vehicle (MEV), set to launch in 2019. Rather than use robotic arms for refueling, the vehicle will act as the engine for an otherwise functional satellite. “Think of a ship in the harbor with a tug,” he says. The MEV mechanically attaches to a client satellite and uses its own fuel to maintain the orbit. After supporting a client for a few years, the craft could disconnect and move on to another target satellite. Northrop Grumman estimates the MEV could operate for 15 years. The company has secured a five-year contract with a communications satellite.

“The MEV servicer is powered by an ion propulsion system that’s far more efficient than a chemical propulsion one,” says Wingo. The move to electric fuel reduces mass and, consequently, launch costs, but it also increases the travel time to orbit. Although green chemical fuels are becoming available, NSR’s Belle says the trend is toward electric power. “We are seeing an interest in driving away from hydrazine” and other chemical fuels, she says. “The European Union is looking at regulations to reduce the availability of hydrazine. It will be a lot harder to get and a lot more money.”

A new future in orbit

Despite the high costs, Restore-L has received a lot of enthusiasm. Still, industry may want to wait and see if the early demonstrations are successful. “Currently, spacecraft manufacturers are seeing a decline in the number of orders for spacecraft,” says NASA’s Kortes. “They are keen to see some industry partners offer satellite services.” Already a handful of commercial players have contracts with early adopters. Northrop Grumman’s vehicle will service a communications satellite. SSL has a customer signed up for servicing. And UK-based Effective Space says it has two clients for its satellite life-extension services.

One approach to lowering costs of satellite servicing could be in-orbit assembly. Rather than build the entire satellite on the ground and then launch it into orbit, the unassembled parts could be packed more economically into multiple launch vehicles. Later a robotic in-orbit servicer managed by humans on the ground could put it all together. “Assembling things in space, in years to come, will be the normal thing,” says Robertson. In-orbit assembly could mean new mission capabilities, lower costs, and even upgrades of satellites after launch. New technologies could be added to satellites as development continues on the ground. “This satellite servicing is in its infancy,” says Robertson. “We probably don’t even realize how it will look in 10 to 20 years.”

More about the authors

Alex Lopatka, alopatka@aip.org