Piezoelectric fibers

DOI: 10.1063/1.3480090

Optical fibers today are ubiquitous, but with few exceptions, they share an important property with their simpler cousins, textile fibers: They’re static, unable to controllably interact with their surroundings. But Yoel Fink and his colleagues at MIT have now demonstrated a way to make functional, piezoelectric fibers tens of meters long.

At the heart of the fibers is a piezoelectric copolymer known as P(VDF-TrFE), chosen because it spontaneously crystallizes into the desired ferroelectric phase; the same material is commonly used in piezoelectric microphones. To control the P(VDF-TrFE) in the fibers, the researchers sandwiched it between layers of conductive carbon-loaded polycarbonate, whose high viscosity ensured that the desired structure was preserved during the fabrication. To make the fibers, the researchers start with layered rectangular or cylindrical preforms some tens of millimeters across. Each preform is heated and then drawn out (stretched) to form a thin fiber with the same shape and layering but with cross sections a factor of 20-200 smaller. Following the application of a strong electric field to align the copolymer, the resulting fibers are uniform, crystalline, and piezoelectric.

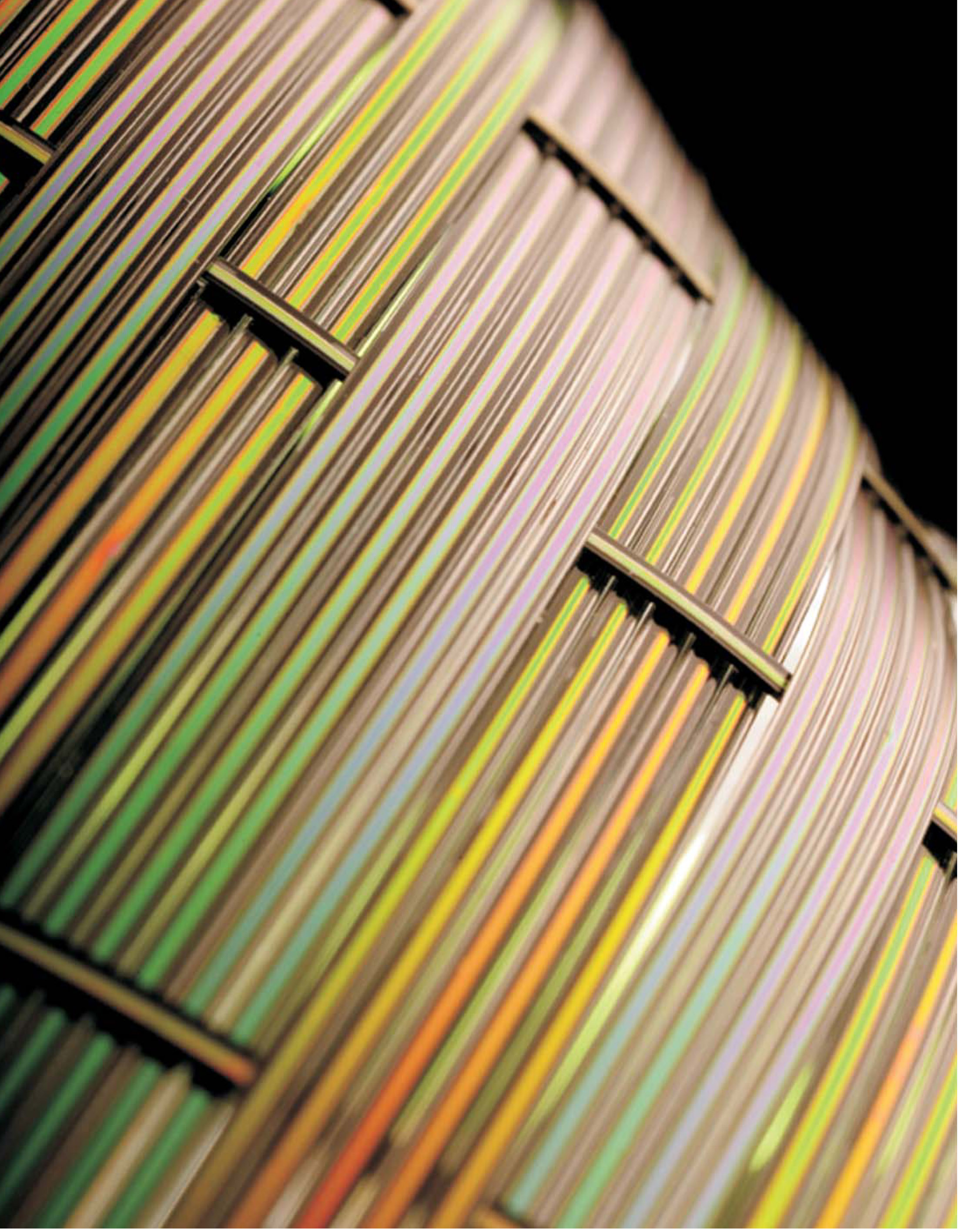

The fibers function both as acoustic detectors and as acoustic actuators, and they can be made in different shapes and configurations by constructing the preform accordingly. Shown here is a weave of rectangular fibers into which Fabry-Perot optical resonators have been fabricated. Each fiber in the warp and weft is about a millimeter wide; the colors are the reflections of the third resonator modes. Such an arrangement could provide an actively controlled optical response as well as pressure transduction over a large area. (

To submit candidate images for Back Scatter, visit http://www.physicstoday.org/backscatter.html

Image courtesy of the Research Laboratory of Electronics at MIT/Greg Hren Photography.