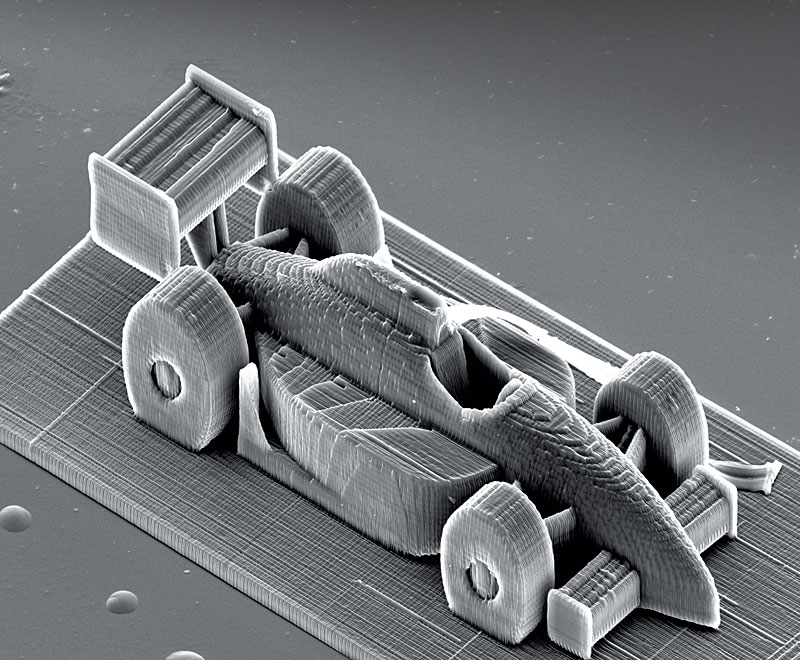

Nano 3D printing hits the fast track

DOI: 10.1063/PT.3.1530

The past 25 years have seen the rapid development of “additive manufacturing,” commonly known as three-dimensional printing (see PHYSICS TODAY, October 2011, page 25

The Vienna technique relies on two-photon polymerization. Femtosecond pulses from an 800-nm laser are focused within a volume of light-sensitive resin. The pulse can trigger the polymerization of the resin, but the process requires the absorption of two photons. That only happens at the focal point, where the intensity is sufficiently strong. As the laser is scanned through the material, it leaves in its wake a solidified line a few hundred nanometers wide. Whereas layer-by-layer techniques constrain the assembly to the surface of the material, two-photon polymerization can occur anywhere in the resin volume. Large overhangs, such as the tail of this micron-scale racecar, can thus be produced.

Two-photon polymerization has traditionally been slow, on the order of millimeters per second. But building on earlier work from 2011 and incorporating a novel photopolymer system with a finely tuned mechanical setup, the Vienna team fabricated this detailed racecar, 285 µm long, in just 4 minutes, with an average polymerization speed greater than 80 mm/s. For larger structures, the researchers anticipate even higher speeds, up to 5 m/s. (See K. Cicha et al., J. Appl. Phys.110, 064911, 2011, and http://amt.tuwien.ac.at/projekte/2pp

To submit candidate images for Back Scatter, visit http://www.physicstoday.org/backscatter.html

Image courtesy of the Vienna University of Technology.