3D printing, inspired by wood

DOI: 10.1063/PT.3.2491

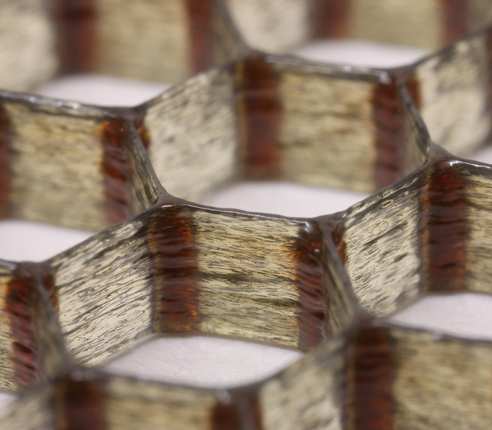

Wood is a ubiquitous, natural example of a composite material: Within its cell walls, cellulose fibers provide structure and strength and are held in place by a matrix of lignin. Brett Compton and Jennifer Lewis of Harvard University have now demonstrated how the additive techniques of three-dimensional printing can be enlisted to manufacture cellular composites whose strength and stiffness nearly match those of wood.

Lori Sanders, Harvard University

In typical 3D printing, a heated and softened plastic extrudes through the printing nozzle, cools, and rehardens. In the researchers’ composite, silicon carbide whiskers and carbon fibers play the reinforcing role of cellulose and are held in place by a matrix of cross-linked epoxy molecules. For 3D printing, the “ink” requires carefully tailored composition and rheology. As the nozzle traces each successive layer of the 3D pattern, the ink has to extrude easily from the few-hundred-micron-wide opening and afterward maintain its filamentary shape and position. Starting with a low-viscosity epoxy resin, the researchers introduced a chemical plasticizer and clay nanoplatelets 100 nm across but only 1 nm thick to achieve the desired viscoelastic behavior. The extrusion process causes the silicon carbide whiskers and carbon fibers to align along the nozzle’s path. Epoxy resins harden through chemical reactions with a curing agent. For household five-minute epoxies, that reaction is fast, but the hardener the Harvard team used gave the ink an extended, 30-day work life at room temperature; the curing was deferred until the sample was heated after the printing was completed.

Compton and Lewis used their ink to print triangular, square, and honeycomb lattices that are exceptionally lightweight yet strong. In the honeycomb lattice seen here, the hexagonal cells are 6 mm across and 3 mm high; the alignment of the black carbon fibers is visible in the cell walls. With their fiber reinforcement and structural matrix, the epoxy composites are an order of magnitude stiffer than the typical polymers of 3D printing, and a factor of two stiffer than the best printed plastic composites. (B. G. Compton, J. A. Lewis, Adv. Mater., in press, doi:10.1002/adma.201401804

To submit candidate images for Back Scatter, visit http://contact.physicstoday.org