X rays peer inside a magnet

DOI: 10.1063/PT.3.3681

Earlier this year two groups observed the first signs of intrinsic ferromagnetism in few-layer two-dimensional materials. (See Physics Today, July 2017, page 16

In a different respect, though, magnetism is widely viewed as a fundamentally 2D phenomenon. Magnetic spin textures—walls separating domains of uniform magnetization, skyrmions, vortices, and other inhomogeneous configurations—are almost always studied in thin magnetic films where the magnetization varies in only two dimensions and is mostly uniform over the film thickness. The films are tens of nanometers thick, an order of magnitude thicker than the 2D materials where the reduced dimensionality disrupts the magnetism itself.

In a bulk material, there’s more room for the magnetization to form potentially useful structures that vary in all three dimensions.

1

But the study of 3D magnetic textures is still in its infancy. One of the things holding back progress is the need for better techniques for measuring magnetism in 3D. Nondestructive imaging of bulk magnetic materials has heretofore been limited to neutron diffraction. Despite some successes (see, for example, Physics Today, April 2009, page 12

Now Claire Donnelly, Laura Heyderman (both at ETH Zürich and the Paul Scherrer Institute in Switzerland), and their colleagues have developed an x-ray tomographic technique that gives a much finer view of 3D magnetization structures. 2 Using hard x rays from the cSAXS beamline at the Swiss Light Source, they collected diffraction patterns from a cylindrical gadolinium–cobalt micropillar at more than a thousand orientations, then computationally reconstructed the internal magnetization field.

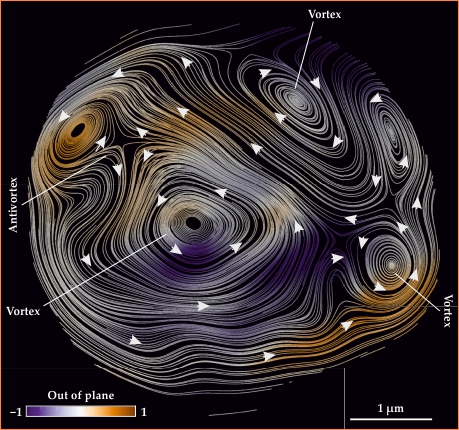

Their resolution, 100 nm, isn’t yet fine enough to see many predicted features, but with the help of a judicious choice of magnetic material, the researchers uncovered a complex arrangement of swirling vortices and antivortices. A slice of their reconstruction is shown in figure

Figure 1.

A slice of a magnetic micropillar imaged with hard x rays. In-plane magnetization is shown by the white streamlines, and out-of-plane magnetization is represented by the colored shading. (Adapted from ref.

What’s inside?

The simplest configuration a magnet can take, whether in a thin film or in bulk, is the single-domain state, with all the magnetic moments pointing in the same direction. Other simple magnetic states include the vortex, in which the moments rotate through 2π along a closed path around the vortex core. Away from the vortex core, the magnetic moments are locally aligned, but near the core, the rapidly changing magnetization is energetically disfavored. The vortex can thus lower its energy by having the magnetization pop out of the plane—either up or down—in a few-nanometer region surrounding the core.

In two dimensions, vortices and other magnetic structures can be imaged with magnetic force microscopy—like atomic force microscopy but with a magnetic tip—and related techniques. Researchers have studied how vortices interact and can be manipulated, how to reverse a vortex core’s magnetization, how spin textures in a small thin-film magnet are influenced by the magnet’s size and shape, and more. (See the article by Chia-Ling Chien, Frank Zhu, and Jimmy Zhu, Physics Today, June 2007, page 40

Increasing the thickness widens the realm of possibilities. In particular, at the intersection of a line-like vortex core and a planar domain wall, the magnetization is changing rapidly in all three dimensions. The point of intersection, called a Bloch point, is a singularity: With no more dimensions to escape to, the magnetization has no choice but to go to zero. In the few-nanometer region around the Bloch point, the magnetization can no longer be treated as a smoothly varying quantity in a continuous material; individual atomic magnetic moments must be considered. 3

At least, that’s what the theory predicts. Bloch points’ nanoscale structure has yet to be directly observed. There’s unambiguous experimental evidence that the singularities exist, but it’s based on using surface magnetization measurements to infer that there must be a Bloch point inside somewhere. 4 Observing them directly requires a way to make high-resolution 3D magnetization measurements. Magnetic force microscopy and similar techniques can’t probe below the surface. And slicing open a bulk object to image its insides—an effective technique in so many fields—is an unworkable option for studying magnetism: Cutting into a magnet changes its magnetization pattern.

Imaging with soft x rays—photons with energy less than 1.6 keV—is an appealing possibility. Resonantly tuned soft x rays can excite electrons into the orbitals that hold an element’s magnetic electrons. For transition metals, the excitation is from the 2p to 3d orbitals; for rare earths, it’s from 3d to 4f. The x-ray absorption signal, then, directly probes the valence electrons responsible for magnetization and thus the local magnetic moment.

Unfortunately, though, soft x rays penetrate no more than 200 nm into a magnetic material. And the next logical step—switching to higher-energy, hard x rays, which penetrate deeper—introduces a new complication. Ideally, one would like to find a hard x-ray atomic resonance that involves the magnetic orbitals: 1s to 3d in a transition metal, for example, or 2p to 4f in a rare earth. Those transitions, however, are spectroscopically forbidden. Hard x-ray imaging must use the 1s to 4p and 2p to 5d transitions instead.

Happily, the 4p and 5d orbitals hybridize slightly with the magnetic ones, so hard x-ray resonances still contain information about magnetization; it’s just weaker and more difficult to extract from a measured signal. To get their 3D images, Donnelly, Heyderman, and colleagues had to pull out all the stops—and invent new ones—both experimentally and computationally.

Nanotomography

The experimental technique, developed with coauthor Manuel Guizar-Sicairos and other collaborators at the Swiss Light Source, is a combination of ptychography and x-ray magnetic circular dichroism (XMCD). In ptychography, instead of collecting a single diffraction pattern with a static beam, one scans the beam back and forth across the sample. Diffraction data from the multitude of overlapping illumination spots make it possible to deduce the sample’s position-dependent effect on both the intensity and the phase of the beam. In XMCD, the process is repeated with both right- and left-circularly polarized x rays, which have opposite responses to the magnetization. Taking the difference between the two polarizations thus isolates a 2D projection of the magnetic signal. 5

Reconstructing the 3D field requires rotating the sample about an axis and collecting data from hundreds of directions. Techniques are well established for such tomographic reconstructions of 3D structures from a collection of 2D projections.

But a problem remained. X-ray absorption probes only the magnetization component that’s parallel to the x-ray beam. So even with sample rotation, the component parallel to the rotation axis is invisible. To measure all components, the researchers rotated the sample about two axes. Tomographic reconstruction of a vector field from that kind of data set was uncharted territory. They had to develop an entirely new set of reconstruction algorithms.

The resolution of their reconstruction was limited by the noisiness of the data they could get with the available beam time. All told, measurements on the GdCo2 micropillar, with a volume of just 351 µm3, took 52 hours. That included some 540 diffraction patterns at each of 1024 orientations (512 per rotation axis); each component diffraction pattern, then, had to be measured in a fraction of a second.

The resulting 100 nm resolution is too coarse to see the magnetic details of most materials. But GdCo2 is special. One characteristic size scale of magnetization structures—such as domain walls—is set by the ratio between the exchange constant (the strength of the interaction among nearby spins) and the magnetic anisotropy (the magnetization’s preference to lie along a particular axis). Because GdCo2’s anisotropy is unusually low, its magnetic textures are large, so a lot can be seen even at 100 nm resolution. Still, the researchers are eagerly looking forward to synchrotron improvements that will refine their resolution further, perhaps by a factor of five in just a few years.

Coauthor Sebastian Gliga of the University of Glasgow in Scotland was crucial to interpreting the results and comparing them to micromagnetic theory. He identified a domain wall that extended most of the length of the pillar; in figure

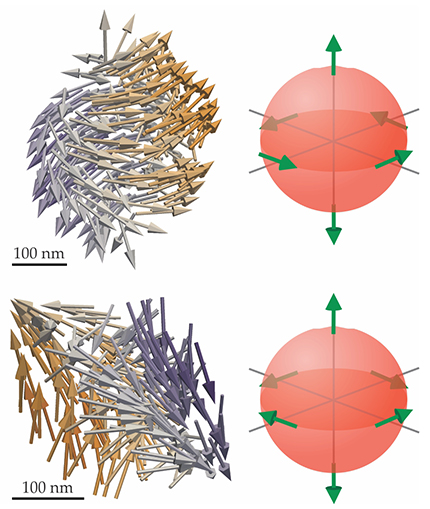

At two locations in the sample, the domain wall intersected a vortex, giving the researchers their first direct view of the long-sought Bloch points, as shown in figure

Figure 2.

Details of two Bloch points, characterized by rapidly changing magnetization in all three dimensions, with the experimentally measured magnetization fields shown on the left and the underlying nanoscale topology shown on the right. The upper panels show a circulating Bloch point, the intersection of a vortex and a domain wall. In the lower panels, the vortex is replaced by an antivortex. (Adapted from ref.

Better performance

New magnetic technologies are emerging all the time, and they don’t all require complicated magnetization states. Headphones, for example, weren’t always small enough to fit in your ears; they were shrunk to that size only after the development of powerful neodymium-alloy magnets. For applications like that, the single-domain state is desired, but there’s no direct way to verify that a bulk magnet is in even that simple state. “The microscopic magnetization structure is important to the magnet’s performance,” says Donnelly, “but it could only be deduced through measurements of bulk properties and surface structure. Now we can see it directly.”

If magnets get even smaller and stronger—or perhaps, to make magnets smaller and stronger—the relationship between magnetic structure and material structure will likely come to the fore. Domain-wall pinning is already a known phenomenon: A moving magnetic domain wall gets stuck on crystal defects or other features. Studying that and similar effects in more detail, in the bulk, and at the submicron scale could lead not only to new magnetic technologies but to optimized performance and reliability for the ones we have.

References

1. A. Fernández-Pacheco et al., Nat. Commun. 8, 15756 (2017). https://doi.org/10.1038/ncomms15756

2. C. Donnelly et al., Nature 547, 328 (2017). https://doi.org/10.1038/nature23006

3. C. Andreas, A. Kákay, R. Hertel, Phys. Rev. B 89, 134403 (2014). https://doi.org/10.1103/PhysRevB.89.134403

4. S. Da Col et al., Phys. Rev. B 89, 180405(R) (2014). https://doi.org/10.1103/PhysRevB.89.180405

5. C. Donnelly et al., Phys. Rev. B 94, 064421 (2016). https://doi.org/10.1103/PhysRevB.94.064421

6. R. G. Elias, A. Verga, Eur. Phys. J. B 82, 159 (2011). https://doi.org/10.1140/epjb/e2011-20146-6

More about the authors

Johanna L. Miller, jmiller@aip.org