White LEDs poised for global impact

DOI: 10.1063/1.2825062

Rural villagers in Nepal rely on kerosene lamps to light their homes, and they aren’t the only ones to do so. Worldwide, around 1.6 billion people—most of them in developing countries—don’t have access to electricity and must rely on fuel-based sources for lighting.

Inadequate lighting represents a significant barrier to future development, according to David Irvine-Halliday, a professor of electrical engineering at the University of Calgary in Canada and founder of the Light Up the World Foundation. LUTW is a nonprofit organization that distributes solid-state lighting systems to rural villages all over the world, including Nepal, Tibet, Pakistan, India, Ghana, and Sri Lanka. It relies on donations from individuals and corporate partners and on support from host countries and other international foundations.

The foundation’s global lighting solution is a combination of two 1-W white light-emitting-diode lamps coupled with a 5-W solar panel and a lead-acid battery, although some systems use pedal generators or even small wind turbines. Unlike incandescent bulbs, LEDs don’t need filaments, so they don’t waste energy through heat losses; the illumination derives solely from electron–hole recombination in the semiconductor material. LEDs are longer-lasting and more efficient than kerosene lamps, and they produce less greenhouse gas emissions.

Irvine-Halliday credits physicist Shuji Nakamura of the University of California, Santa Barbara, with developing the necessary technology to bring solid-state lighting to the developing world. Nakamura invented the white LED while employed by Nichia Corp in Japan. The first white LEDs generated light inside a crystal of gallium nitride, powered by a 3-volt battery.

First, Nakamura developed a new technique for growing gallium nitride. Then he discovered he could make a brighter, more efficient blue LED by adding indium to the gallium nitride structure. That technique lowered the frequency of the emitted photons from UV to blue light. By sandwiching a layer of InGaN between two cladding layers of the wider-bandgap GaN, he created a quantum well effect, confining electrons to two dimensions instead of three and giving them a sharper density of states than is found in bulk materials.

Adding just a fraction more indium to the mix resulted in a green LED. To make a white LED, Nakamura added a yellow phosphor coating of cerium-doped yttrium aluminum garnet crystals. The yellow light stimulates the red and green photoreceptors of the eye and, when mixed with the blue light emitted by the LED chip, gives the appearance of white light. Finland’s Millennium Prize Foundation, which honored Nakamura in 2006, equated his technological breakthroughs to Thomas Edison’s invention of the incandescent lamp.

Energy efficiencies continue to improve. White LEDs now have energy efficiencies of 60% in the laboratory and 25–52% in actual use, which is a significant improvement over incandescent bulbs at 5% and fluorescent lighting at 15–25%. Nakamura believes white LEDs could reach 90% efficiency in the laboratory by 2011.

A major factor is cost. LED prices are currently about 10 times higher than incandescent bulbs, although they are cheaper in the long run because they last much longer and use less energy. LUTW’s system costs about $150, “far too much money to expect those at the base of the economic pyramid to have on hand,” Irvine-Halliday admits. However, he realized that people in rural villages were paying that much per year for kerosene. So he devised a payment plan in which they can pay for the system in installments, on a par with what they were spending on kerosene. After one year, they will own the system outright, with minimal maintenance costs of around $2 per year.

Solid-state lighting is beginning to make inroads in the US as well. The Department of Energy estimates that 22% of all the electricity produced in this country is consumed by lighting, and widespread deployment of LED systems could cut that consumption in half and reduce costs substantially. For instance, Philadelphia replaced more than 14 000 of its red traffic light signals with LEDs, for a projected five-year savings of $4.8 million. Raleigh, North Carolina, is in the process of making the switch to LEDs in its streetlights—as is Toronto, Canada—as part of the LED City program, an industry—government initiative dedicated to promoting LED lighting.

Another LED City partner, Ann Arbor, Michigan, switched 1000 of its streetlights entirely to white LEDs in November. City officials anticipate a 3.8-year payback on their initial capital investment and estimate they could save as much as $100 000 per year in the long term. The action could also remove about 294 tons of carbon dioxide annually that would otherwise be emitted into the atmosphere. Eventually, the city plans to switch all of its streetlights to white LEDs.

Currently, LUTW has its LED systems installed in 20 000 homes in 42 countries, but Irvine-Halliday’s vision is to light millions of homes. “We’re just barely scratching the surface,” he says of the foundation’s achievements to date. “It’s a matter of getting the word out. People need to know that there is a proven solution for lighting up the developing world.”

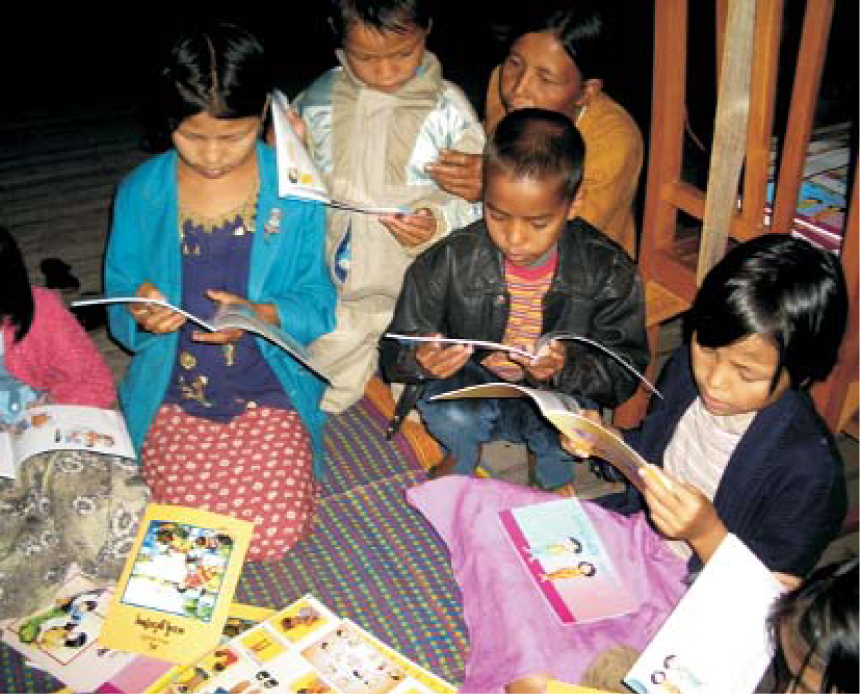

Children reading by the light of white LEDs installed at Golden Island Cottages, Inle Lake, Myanmar.

NINA BAINS CASSILS