Tobacco cells infused with carbon nanotubes feel the heat

DOI: 10.1063/PT.3.2803

An emerging approach in bioengineering strives to enhance plant function by combining biology and nanotechnology. Last year, MIT’s Michael Strano, his postdoc Juan Pablo Giraldo, and their colleagues charted one path in that approach, which they call plant nanobionics, by infiltrating a plant’s chloroplasts with semiconducting carbon nanotubes to increase photosynthesis. Once inside the chloroplasts, the nanotubes self-assembled alongside the photosynthetic proteins there. 1

Conveniently, the plant did most of the assembly work. To prompt a leaf of Arabidopsis thaliana—a plant in the mustard greens family—to take up carbon nanotubes, Strano’s team had only to push a nanotube-filled solution through the leaf surface. Thanks to nanotubes’ natural affinity to fats, the chloroplasts’ outer lipid envelope pulled them inside the organelles. Among other advantageous properties, nanotubes can absorb a broad spectral band of photons, and plant leaves coated with them were found to absorb in the near-IR, a band not captured by chloroplast pigments. The treated plant leaves exhibited 30% greater photosynthetic activity than untreated ones.

Materials scientist Chiara Daraio, her postdoc Raffaele Di Giacomo (both at ETH Zürich), and microbiologist Bruno Maresca (University of Salerno in Italy) have now exploited carbon nanotubes to augment another enviable feature of a plant—its temperature response. 2 For more than half a century, biologists have known that living plants respond to changes in air temperature through changes in their electrical conductivity. But that sensitivity disappears when they die. By growing tobacco cell cultures in the presence of the nanotubes, the researchers permanently stabilized the temperature response and extended its range.

Changing course

The team didn’t set out to make a thermometer. Gram for gram, carbon nanotubes are two orders of magnitude stronger than steel and are exceptional shock absorbers. Daraio’s original plan was to synthesize a stronger, more resilient, lightweight material from nanotube-reinforced plant fibers. Before Di Giacomo joined Daraio’s group, he and Maresca had laid the foundation for meeting that goal. 3 When added to a growing culture of fungal or tobacco cells, carbon nanotubes partially penetrate the cell walls and form a dense intracellular network that confers structural integrity and additional electrical conductivity to the resulting composite. In the case of the tobacco cells, the two researchers noticed that once the cells dried from an originally gel-like consistency, they took on some of the mechanical properties of wood.

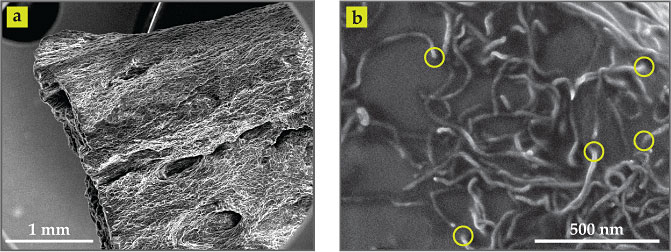

Even dehydrated, the composite, dubbed cyberwood and shown in figure 1, can be fashioned into an electrical circuit. After affixing gold contacts to a sample and applying a voltage across it, Di Giacomo, then working with Daraio, found that the material’s electrical resistance R decreased by almost three orders of magnitude as the temperature T slowly rose from 35 °C to 75 °C. That corresponds to an effective temperature coefficient of resistance (TCR) of −1730% K−1, where TCR = (ΔR/R0)/ΔT, and R0 is the minimum resistance in the temperature range. By comparison, vanadium oxide, the sensor of choice in today’s thermal cameras, has a TCR of about −6% K−1 in a comparable range between room temperature and the material’s metal–insulator transition.

Figure 1. (a) Cyberwood is the term coined to describe the dehydrated result of growing a culture of tobacco cells in the presence of carbon nanotubes. (b) As the cells grow in a nutrient-filled flask, the thread-like nanotubes partially penetrate (inside the yellow circles) the gelatinous cell and self-assemble into a dense network of intracellular connections. The network lends the composite mechanical strength and electrical conductivity. (Adapted from ref.

Measurements of the cyberwood revealed an unchanging sensitivity up to approximately 100 °C, far above temperatures that are physiologically relevant to plants. The resistance change also occurs within seconds, much faster than live plants are thought to respond to warming or cooling. Nonetheless, through a series of experiments the researchers determined that the extreme sensitivity of cyberwood is due to a common behavior in plants—the uptake or release of calcium ions from pectin.

Well known as the carbohydrate molecule whose gelation properties bind sugars and fruits into jellies and pies, pectin is made of polysaccharide chains, cross-linked by Ca2+ ions, that confer strength and expansibility to cell walls. As it warms or cools, pectin softens or stiffens at a rate that depends exponentially on its temperature. Even slight changes in temperature alter the conformation of the cross-linked chains; warming causes them to unzip from each other, which releases ever greater numbers of free ions that, in turn, alter the material’s conductivity.

Zombie cells

Ironically, improving the plant cells’ performance as sensors entails killing them. Living tobacco cells, unreinforced by nanotubes, also exhibit a highly sensitive temperature-dependent resistivity. But that response to temperature cycling is transient and reliant on how well the cells retain moisture. They would, as Di Giacomo puts it, “sometimes collapse into dust” above 55 °C, as their water evaporated and they became structurally unstable. Cyberwood, by contrast, tested over an 18-month period, suffered no such deterioration unless heated to much higher temperatures. The nanotubes provide a permanent conductive pathway and substitute for water in the dehydrated material.

Even dead plant cells can absorb water. And even slightly varying humidity levels complicated the team’s measurements of conductivity, which rises by a factor of 25 when the cells’ moisture content changes from 0% to 6%. The sensitivity of cyberwood conductivity to humidity is unrelated to the presence of divalent Ca2+ ions, though, and can be disentangled from the temperature response.

As a device, cyberwood can thus serve as a humidity sensor as long as temperature is constant. Or, if encased in cellophane to keep its moisture constant, it can serve as a heat sensor. As shown in figure 2, the placement of a hand different distances from the cyberwood produces easily discernable and near-immediate changes in its current.

Figure 2. When cyberwood has a voltage applied across it, it becomes a heat sensor. In one experiment, a sensor is placed in an open oven at 23 °C and constant relative humidity. The plot shows variations in current when an experimenter’s hand is then brought close to the sensor, starting at a distance of 19 cm. Between each position, held for 30 s, the hand is quickly moved away. As the hand is placed ever closer, the current ramps to a higher value, only to fall again to the 23 °C reference current after the hand is withdrawn. (Adapted from ref.

Ions and genes

Temperature is an important evolutionary driver for plant survival insofar as it limits where and when plants can grow and flower. Still puzzling, though, is why they would evolve so rapid a response, if it is, in fact, more than just a physical property of pectin. Biologists often think of plants as transcriptional machines that adapt in response to some environmental cue by expressing some genes or repressing others.

Five years ago biologists Vinod Kumar (John Innes Centre in the UK) and Philip Wigge (now at the University of Cambridge) published an account of how that might happen 4 in the same kind of mustard greens Strano and his colleagues would later study. They found that changes in how tightly the DNA is packaged in the cell have a direct influence on gene expression: As the cell warms, its DNA partly unwraps, and the altered conformation seems to cause genes to turn on or off. But that takes place on the scale of minutes, not seconds. And no one has yet identified a molecular trigger for the unwrapping. “The million dollar question,” says Wigge, “is whether the release or uptake of Ca2+ from pectin also signals gene expression.”

Di Giacomo, Daraio, and Maresca are more interested in the practicality of their new material. Although inexpensive, scalable in size, and exceedingly sensitive, cyberwood is tricky to calibrate in devices—a thermal camera, for example—because of the natural complexity of plants. Porosity, surface charge, and pH all influence the transport of ions within a cell wall. To work around the difficulty, the researchers plan to build devices from only extracted pectin and nanoparticles.

References

1. J. P. Giraldo et al., Nat. Mater. 13, 400 (2014). https://doi.org/10.1038/nmat3890

2. R. Di Giacomo, C. Daraio, B. Maresca, Proc. Natl. Acad. Sci. USA 112, 4541 (2015). https://doi.org/10.1073/pnas.1421020112

3. R. Di Giacomo et al., IEEE Trans. Nanotechnol. 12, 1026 (2013). https://doi.org/10.1109/TNANO.2013.2285438

4. S. V. Kumar, P. A. Wigge, Cell 140, 136 (2010). https://doi.org/10.1016/j.cell.2009.11.006