Three-dimensional printing of living material

Adapted from S. Gantenbein et al., Nat. Mater. 22, 128 (2023)

Unlike conventional synthetic materials, which degrade over time, biological materials such as silk, cellulose, and wood can grow, regenerate, and adapt to their environment. For nearly two decades, that fact has inspired the creation of novel synthetic materials. By combining material-producing microorganisms and abiotic building blocks, researchers have made self-healing concretes, antibiotic-releasing surfaces, and other custom-engineered materials.

André Studart

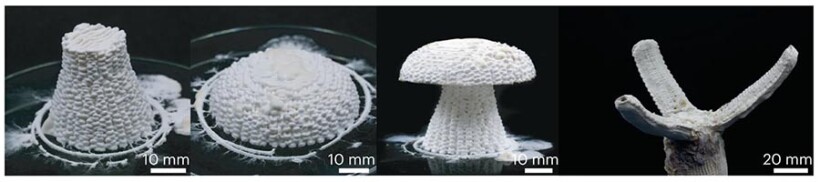

In the researchers’ experiments, the hyphae were able to grow across macroscopic defects in the lattice—cracks up to 2 mm across. And so long as the fractured parts of the lattice had sufficient nutrients, the mycelial film healed into stronger and stiffer structures. On each piece, the front of the hypha grew across the lattice at a rate of 0.6–0.7 mm/day. Besides self-healing, the researchers demonstrated that the growth of their mycelium network could be used to merge differently printed hydrogels into a single, more complex object. The confocal microscopy images here illustrate the potential of the mycelium-laden hydrogels. The third object is formed by combining the first two. And the fourth object in the set shows a robotic gripper. (S. Gantenbein et al., Nat. Mater. 22, 128, 2023