Laser beam remodels liquid crystals on the fly

DOI: 10.1063/PT.3.2801

Contrary to the conventional textbook picture, not all solids completely lose their order when they melt. Some molecular solids instead form liquid crystals, materials with the molecular orientational order of a solid but the mobility of a fluid. Such liquids have attractive optoelectronic properties: Their molecular ordering makes them birefringent, and because the molecules can be manipulated with electric fields, that birefringence can be modified with the flip of a circuit switch. (See the article by Peter Palffy-Muhoray, Physics Today, September 2007, page 54

To create liquid crystals for devices, however, you need to be able to direct their alignment. One of the most popular strategies is also a simple one: Rub two polymer-coated glass plates with a cloth, face them to form a cell, and fill the cell with a liquid crystal of elongated molecules. The rubbing stretches the polymers and imprints the coating with microscale grooves, and the liquid crystal’s molecules align parallel with those grooves. Many such cells arrayed together as pixels can be used for visual displays, tunable lenses, and other devices.

More sophisticated variations on the rubbing technique exist, but the principle is generally the same: Imprint some preferred directional alignment onto the interior walls of a cell, and the liquid crystal’s molecules will follow. Some applications, however, require finer optical control than can be achieved with a patchwork of uniformly imprinted cells. Ideally, one would like to control a liquid crystal’s alignment at length scales smaller than the cell.

Now Giorgio Mirri, Miha Škarabot, and Igor Muševič of the Jožef Stefan Institute in Ljubljana, Slovenia, have devised a convenient way to do just that. They can pattern microdomains of varying shape and orientation into a liquid-crystal cell by using an IR laser as a stylus. 1 As the laser sweeps across the liquid crystal, it rotates the molecules in its path to an angle that depends on the direction in which it’s scanned.

An island adrift

To be sure, there are other ways to micropattern liquid crystals. For instance, one can use photoalignment—a technique analogous to photolithography—to pattern the plates before assembling them into a cell. 2 But that approach works only on special light-responsive molecules. And, even then, precisely superimposing micropatterned plates carries its own challenges. A benefit of the new method is that it allows one to write and erase microdomains after the cell is built.

Mirri and company happened upon the technique while using a laser as optical tweezers for colloidal particles embedded in liquid crystalline matrices. The laser locally heats the liquid crystal past its clearing temperature, above which the liquid loses its orientational order. The result is a small island of disorder in the otherwise ordered fluid. The relatively large colloidal particles are attracted to the ordered–disordered interface, so the laser can be used to latch onto and manipulate them. 3

Mirri noticed, however, that the tweezers left subtle trails—thin lines along which the liquid crystal’s molecular orientation was permanently perturbed. The researchers had expected the molecules to reassume their original orientation upon cooling. Instead the molecules appeared to adopt a new one.

Mirri and his colleagues eventually realized that their laser-heated islands weren’t entirely free of order: The molecules just inside an island’s perimeter tended to align tangent to the boundary, as shown in figure 1a. So as the laser spot moves, the molecules in its path heat and recrystallize in the orientation prescribed by the spot’s trailing edge.

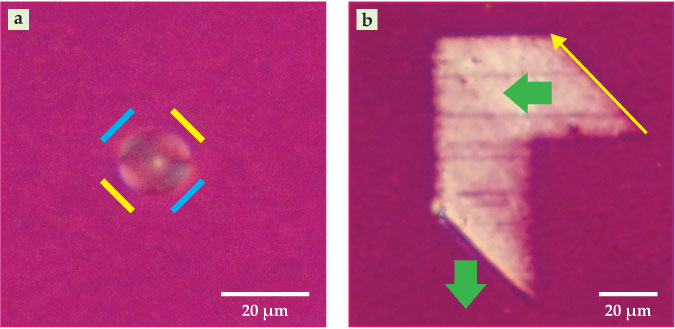

Figure 1. A liquid-crystal makeover. (a) A sufficiently intense IR laser creates a small spot—here, roughly 15 µm across—in which a liquid crystal’s orientational order is temporarily destroyed. Molecules near the edge of the spot orient tangent to its perimeter. Here, transmitted light has been filtered with polarizers and waveplates such that regions of horizontal and vertical orientation appear magenta, regions oriented at 45° appear bluish, and those oriented at −45° appear yellowish. (The blue and yellow bars serve as color legends.) (b) When a smaller laser spot is quickly scanned in one direction (yellow arrow) and slowly translated in another (green arrows), molecules in its path reorient parallel to the scanning direction. (Adapted from ref.

Crucially, that realignment occurs not only in the interior of the cell but in the molecular layer adjacent to the confining plates. Those molecules tend to adhere to the wall—a phenomenon known as the surface-memory effect. So once the new laser-induced alignment is established, it’s effectively anchored in place.

Figure 1b illustrates how the researchers exploit the laser realignment to create two-dimensional microdomains. They scan the laser repeatedly along one direction (indicated in the figure by the yellow arrow) with a period shorter than the time it takes the heated molecules to reform a liquid crystal. The result, then, is not a circular island of disorder but a long, slender one. As that island is translated across the liquid crystal, the molecules in its path reorient parallel to the laser scanning direction.

The writing’s on the wall

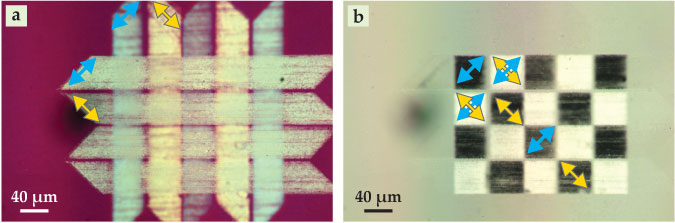

If a cell is sufficiently thick, roughly 5 µm or larger, Mirri and company’s technique can be used to address the vicinity of each fluid–plate interface separately. The cell in figure 2a, for instance, was imprinted with a different pattern at each interface. At one interface, the researchers imprinted alternating rows having molecular orientations of 45° (blue arrows) and −45° (yellow arrows); at the other, they imprinted alternating columns with the same orientations.

Figure 2. A thin cell consisting of a liquid crystal sandwiched between two plates is viewed normal to its surface. (a) At one liquid–solid interface, alternating rows with molecular orientations of 45° and −45° (blue and yellow arrows) were imprinted by laser realignment. At the other interface, alternating columns of 45° and −45° were imprinted. (Originally, the liquid crystal’s orientation was horizontal.) Where the two interfaces’ alignments are orthogonal, the intervening liquid forms what’s known as a twisted nematic crystal. (b) When the cell is backlit and viewed between crossed optical polarizers, only the twisted nematic regions appear bright. (Adapted from ref.

Viewed normal to the cell’s surface, the crisscrossing rows and columns form a grid. At those crossings where the orientations at the near and far fluid–plate interfaces are orthogonal, the intervening liquid crystal forms what’s known as a twisted nematic phase: The molecules in any surface-parallel layer coalign, but the orientation rotates slightly from one layer to the next.

When the cell is backlit and viewed between crossed optical polarizers, only the twisted nematic regions appear bright; the twists rotate the polarization of the transmitted light, which allows the light to pass through both polarizers. That gives rise to the checkerboard pattern shown in figure 2b. Indeed, twisted nematic crystals provide the basis for LCD pixels. Sandwiched between crossed optical polarizers, they can be switched reversibly from their native bright state to an opaque state by applying an electric field that destroys the twist.

Hiroshi Yokoyama of Kent State University thinks that Mirri and company’s laser approach could provide a simple, cheap way to imprint liquid-crystal cells with the kinds of sophisticated patterns needed to build, say, aberration-free lenses or LCDs that have good wide-angle visibility. He adds that another advantage is the possibility of pinpoint repair: “Currently, if an LCD TV comes off the assembly line with even one defective pixel, the entire TV gets discarded. So an approach like this, where you can fix pixels after the fact, could potentially save a lot of money.”

But Yokoyama cautions that several technical hurdles remain to be cleared. For instance, researchers will need to demonstrate that the laser-patterned cells can withstand the rigors of repeated on–off cycling. In a preliminary experiment, the technique showed promise. When the Slovenian team repeatedly heated and cooled their cells past the clearing temperature, the laser-drawn patterns were consistently recovered—thanks, presumably, to the surface-memory effect.

Still, Muševič concedes that the twisted nematic cells “obviously aren’t perfect.” The dark squares aren’t completely dark, he notes. “A manufacturer would look at that and say, ‘That’s no good.’” But the group hasn’t yet attempted to optimize the fabrication process. “We’re generally more interested in the fundamental science,” he says. “But I think there are many options for improving the technique.”

References

1. G. Mirri, M. Škarabot, I. Muševič, Soft Matter 11, 3347 (2015).https://doi.org/10.1039/C5SM00282F

2. K. Ichimura, Chem. Rev. 100, 1847 (2000).https://doi.org/10.1021/cr980079e

3. I. Muševič et al., Science 313, 954 (2006).https://doi.org/10.1126/science.1129660