G8 nations commit to building a score of CO2 sequestration demonstration projects

DOI: 10.1063/1.2982113

The US government plans to sponsor half of the 20 commercial-scale demonstrations of carbon capture and storage (CCS) technology that the world’s biggest industrialized nations have collectively pledged to get under way in the next decade. Heads of the G8 nations announced their commitment to deploy CCS as part of their goal to slash their nations’ carbon emissions in half from current levels by 2050.

According to a joint communiqué issued at their 6–9 July summit in Japan, the G8 leaders said they “strongly support the launching of 20 large-scale CCS demonstration projects globally by 2010 … with a view to beginning broad deployment of CCS by 2020.” Both the number of and the timetable for the demonstrations are taken from a report by the International Energy Agency, prepared at the request of the G8 leaders. It is just 1 of 17 “technology roadmaps” that the IEA said will need to be followed in order to achieve the 50% reduction in carbon dioxide emissions.

At a Senate hearing in June, Neil Hirst, director of energy technology and R&D for the Paris-based IEA, warned that the size of that challenge should not be underestimated. On average, 35 coal-fired power plants with CCS must be installed each year from now through 2050, on top of new investments in wind, solar, and nuclear energy, if the world is to cut carbon emissions in half. “Given the challenges of establishing a single CCS project today, this is really an energy technology revolution,” Hirst said. The UN’s Intergovernmental Panel on Climate Change (IPCC) estimated last year that broad deployment of CCS could reduce CO2 emissions by as much as 55% over the coming century.

At the federal level, a number of actions have taken place during recent months that could accelerate CCS commercialization, but setbacks have occurred as well. In June the Department of Energy announced a plan to fund several commercial-scale CCS demonstration projects that will sequester at least 1 million tons of CO2 a year. Although DOE’s request for proposals didn’t specify the number of projects it plans to support with about $1.2 billion over several years, a top department official indicated that there are likely to be at least three.

A troubled future

The June solicitation resulted from a restructuring of FutureGen, a 2003 initiative by which DOE would share the cost of building an entire integrated gasification combined cycle (IGCC) electric-generating station and the associated CCS system. Energy Secretary Samuel Bodman pulled the plug on the project in January, citing cost estimates that had doubled from the original $1 billion projection and the unwillingness of a 13-member industry consortium to pick up a greater share of the overruns. DOE had agreed to pay 74% of the project’s cost at the outset, far more than the traditional 50–50 cost sharing it offers in most of its cooperative agreements with industry. Moreover, Bodman reasoned that with commercial-scale IGCC plants already in operation, the FutureGen resources could be spent more productively on developing CCS technologies alone.

But the cancellation created an uproar in Congress. Senate appropriators zeroed out DOE’s $290 million fiscal year 2009 request for the restructured program, and Senator Richard Durbin (D-IL) has blocked Senate consideration of President Bush’s nominee for deputy energy secretary, calling for the fate of FutureGen to be left to the next administration. The House Committee on Science and Technology meanwhile continues its probe into the project. In a 28 July letter to Bodman, committee chairman Bart Gordon (D-TN) and two other panel Democrats demanded that DOE turn over internal documents chronicling the decision-making process.

In August DOE announced that it would make available up to $340 million more in FY 2009 to demonstrate CO2 capture and storage technologies at a commercial scale. Although companies must pay at least half the cost of the demonstrations, the minimum scale, at 300 000 tons of CO2 captured and sequestered per year, is less than the 1 million tons required for DOE’s other commercial-scale grant offerings.

Proceeding on a separate but parallel track are seven DOE-sponsored regional carbon sequestration partnerships that have been under way since 2003. Each of those projects is expected to enter its commercial deployment phase by 2010, DOE Undersecretary Raymond Orbach told the Senate Committee on Energy and Natural Resources in June. DOE is splitting the cost of those projects with 41 state governments and four Canadian provincial governments. They will test the feasibility of long-term CO2 storage in a variety of geological formations that occur across the continent. Set to run through 2017, the large tests will build on results from smaller field tests that are being held at 25 locations around the US. The partnerships do not specifically address the capture of CO2 from fossil-fuel burning, however, and in most cases the CO2 will be obtained from natural gas and other non-coal sources.

A $1 billion fund

On the positive side, a House committee moved toward approving legislation to finance additional R&D on CCS by raising $1 billion per year through an annual levy of about $10 on residential electricity bills. Sponsored by Representative Rick Boucher (D-VA), HR 6258 is likely to be marked up soon by the Committee on Energy and Commerce’s energy subcommittee, which Boucher chairs. Indicative of the bill’s bipartisan support, Texas Rep. Joe Barton, the ranking Republican on the full committee, said the bill is likely the only measure related to climate change that will become law this year.

The Environmental Protection Agency in July announced its proposed rule for regulating carbon sequestration under the Safe Drinking Water Act. EPA assistant administrator Benjamin Grumbles said the proposal will ensure that injection wells are properly sited, built, monitored, and tested, and that their operators will bear financial responsibility throughout the sites’ lifetime. Grumbles said the rule is expected to become final in late 2010 or early 2011, and he acknowledged that it does not address liability under other statutes that govern hazardous wastes. Although CO2 is nontoxic, its injection under high pressure could displace highly saline water that is present in many of the underground formations that are suited for CO2 storage, and potentially contaminate drinking-water wells. It’s also possible, if unlikely, that heavy metals or other toxic substances in the subsurface might be pushed into potable water supplies by the CO2, Grumbles told the House energy committee.

The underpinning science and technology for storing CO2 is a bit further along the development path than is gas-capture technology, says Thomas Feeley, technology manager at DOE’s National Energy Technology Laboratory in Pittsburgh, Pennsylvania. That’s mainly because petroleum producers have long used CO2 injection to help boost production from old oil fields, a process known as enhanced oil recovery. At one such operation in Saskatchewan, Canada’s Weyburn oil field, monitoring has been under way since 1997 to determine how well the injected CO2 stays put.

Long-term monitoring of the injection wells and surrounding areas will be required to ensure that CO2 isn’t escaping. Although the experience gained from enhanced oil recovery will be useful, Grumbles said, the volume of gas to be stored in CCS is far greater, and required storage times are much longer.

Norway is first

The world’s first commercial-scale CO2 storage operation motivated solely by climate change concerns is in the North Sea, where since 1996 Norway’s 63% government-owned StatoilHydro has injected beneath the seabed about 1 million tons a year of CO2 separated from undersea gas production. Statoil-Hydro was motivated by a tax of about $50 per ton that Norway imposes on industrial CO2 emissions. In April the company initiated a similar CO2 injection operation at a second North Sea gas field, storing the greenhouse gas at a rate of 700 000 tons per year. Energy firm BP p. l. c. and its partners have since 2004 been annually sequestering about a million tons of CO2 separated from natural gas production at Algeria’s In Salah field.

To date, technologies for capturing CO2 from coal combustion have been demonstrated only in the laboratory or at most on the pilot scale, says Feeley. For coal technologies, the pilot scale ranges roughly from

DOE’s target is to find postcombustion capture technologies that will increase the cost of electricity generation by no more than 45% from its current level, and for precombustion capture, by no more than 20%. Edward Rubin, an engineering professor at Carnegie Mellon University, estimates that a CCS system for a 400-MW coal plant would cost between $700 million and $1 billion to build and operate for five years. “Despite a lot of talk and some serious commitments by a number of countries, there today is not a single large-scale CCS project at a coal plant anywhere in the world that has the full financing needed to proceed,” he told the House energy committee.

Capture candidates

The leading candidate technologies for postcombustion capture today are advanced chemical solvents, sorbents, and membranes, according to Feeley. In late July DOE awarded 15 multiyear, cost-shared grants, valued at $36 million, to support carbon capture development projects. Ranging from $700,000 to $5 million, the projects cover a broad range of capture approaches that also include oxygen combustion and chemical looping, which involves the use of chemical carrier particles to transport oxygen from an oxidizing reactor to a combustion chamber.

Powerspan Corp is set to begin a demonstration next year of its aqueous ammonia capture process at a Basin Electric Power Cooperative plant in North Dakota. Powerspan estimates it will capture about 1 million tons of CO2 a year. The company is currently testing the technology at a FirstEnergy Corp generation station in Ohio and capturing about 20 tons of CO2 a day.

Wisconsin’s We Energies is hosting a demonstration of Alstom Power Inc’s chilled ammonia solvent technology at the power plant in Pleasant Prairie, treating 1% of the flue gas from a single boiler. The year-long experiment, which also involves the Electric Power Research Institute Inc, is due for completion this winter. But the project’s partners say that it’s already apparent that using the process will be less expensive than switching to IGCC.

Another technology approach is to burn coal in a pure oxygen environment, producing a flue gas containing a much higher concentration of CO2. That would simplify the compression of CO2 into a liquid state for transport to the injection site. But cheaper processes for oxygen production will need to be developed to improve the economics, Feeley says.

Dave Luebke, an engineer in the office of research and development at the Department of Energy’s National Energy Technology Laboratory, examines membranes used in NETL research on CO2 separation. The membranes are among the technologies being explored to capture CO2 generated from coal combustion for underground sequestration.

National Energy Technology Laboratory

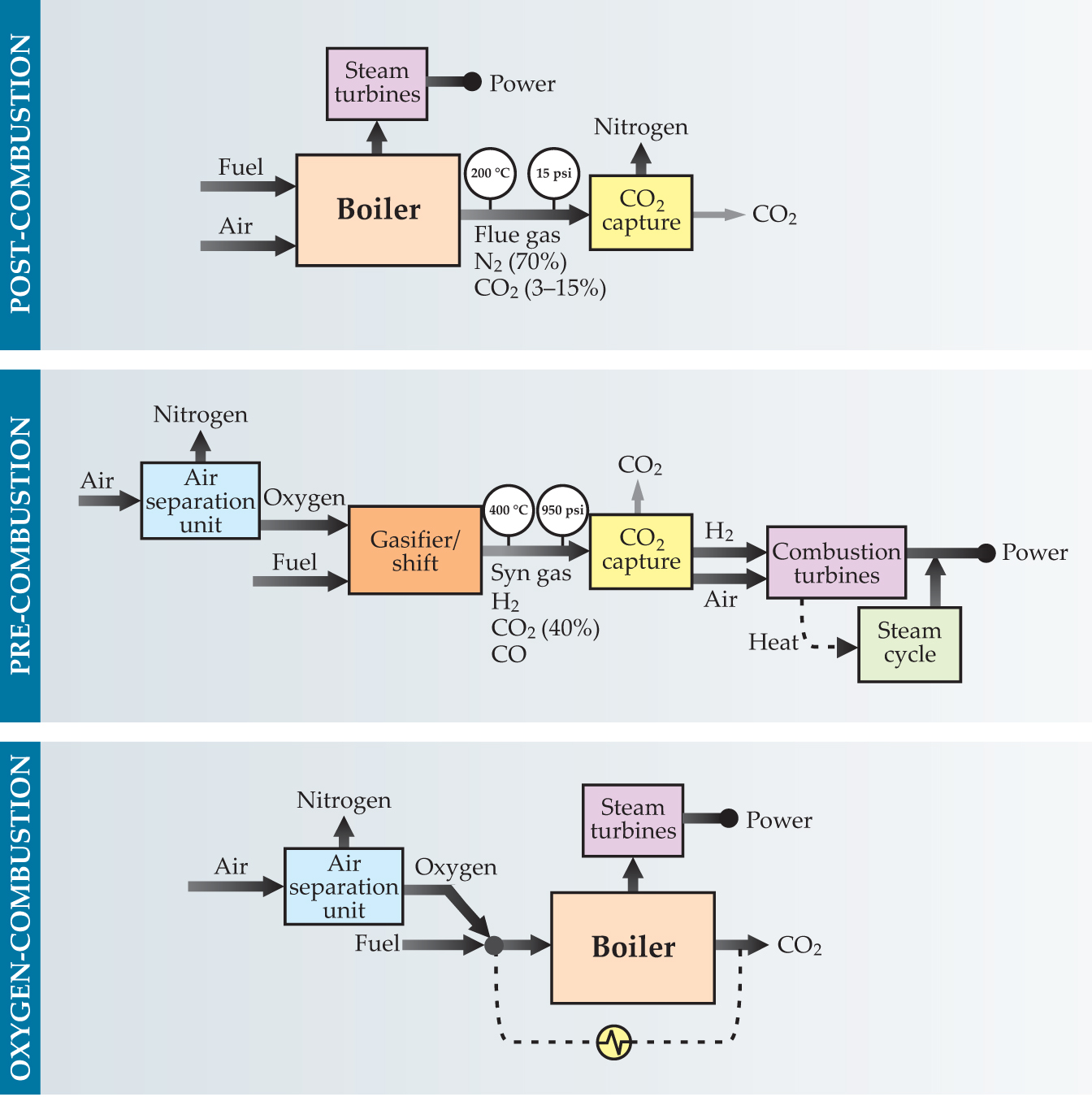

A schematic of three principal technology approaches being tested for CO2 capture from a coal-fired electrical generating station.

National Energy Technology Laboratory

More about the authors

David Kramer, dkramer@aip.org