Ceramic nanolattices hold up under pressure

DOI: 10.1063/PT.3.2166

Apply a large enough stress to a piece of brittle material and it will break—most likely at a preexisting flaw or weak spot. Flaws thereby reduce the fracture strength of real materials relative to their theoretical maxima, sometimes by orders of magnitude. That reduction can be well predicted by the expected statistical distribution of flaw sizes, which depends on the sample’s size.

Reduce the sample’s dimensions below a micron or so and the picture changes. Submicron single crystals of metal or ceramic, whether they contain flaws or not, are much stronger than their bulk counterparts.

1

Furthermore, a submicron sample is no more likely to break at a flaw than anywhere else. The reasons for that size effect remain unclear. But it’s been noted that fracture-resistant biomaterials—such as shells, bone, and tooth enamel—are made up of just such submicron mineral crystals embedded in a protein matrix.

2

(For more on the structure and properties of bone, see the article by Rob Ritchie, Markus Buehler, and Paul Hansma, Physics Today, June 2009, page 41

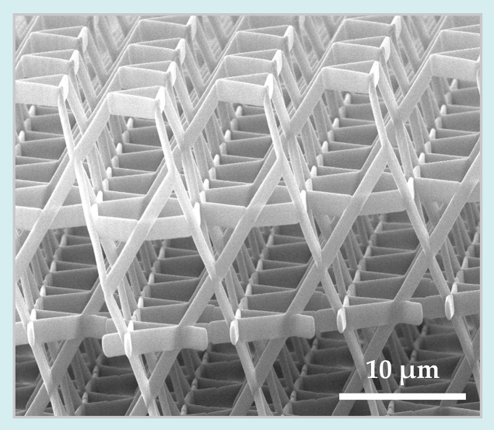

Now Julia Greer and colleagues have taken a step toward exploiting the size effect to produce strong, lightweight materials. 3 They fabricated lattices with submicron dimensions, such as the one shown in figure 1, made up of hollow struts of titanium nitride, a brittle ceramic. Under deformation, the lattices exhibited material properties close to the theoretical limit for TiN.

Figure 1. A hollow ceramic nanolattice with a three-dimensional kagome structure. Each of the several-micron-long struts is a tube with an elliptical cross section, 1 µm × 250 nm, and a wall thickness of 75 nm. (Courtesy of Lucas Meza and Lauren Montemayor.)

Smaller is stronger

Two years ago researchers at HRL Laboratories in Malibu, California, and their collaborators (including Greer) developed a technique for building hollow metal lattices.

4

(See Physics Today, January 2012, page 13

Greer and colleagues used similar techniques to construct their TiN lattices, with some important modifications to allow them to reach a 100-times-smaller size scale. First, to produce a polymer scaffold using a negative photoresist (a liquid polymer that hardens when exposed to bright light), they programmed a computer-controlled focused laser to “draw” the desired three-dimensional structure in the liquid photoresist. Then they deposited alternating monolayers of titanium and nitrogen onto the scaffold to form a 75-nm layer of TiN. Finally, they etched away the polymer scaffold using an oxygen plasma treatment.

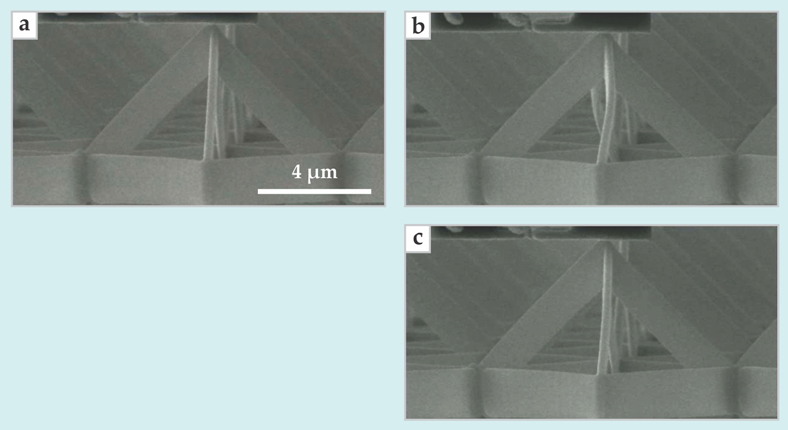

To test the strength of their TiN lattices, the researchers applied a compressive load while observing the system with a scanning electron microscope, as shown in figure 2. When an octahedral lattice was distorted until it broke, it exhibited a tensile strength of 1.75 GPa. (Even though the lattice as a whole was compressed, the failure occurred in a component that was under tension.) In comparison, the theoretical tensile strength for flawless TiN is estimated to be 3.27 GPa. Typical real bulk samples of TiN and other brittle ceramics have tensile strengths in the tens to hundreds of megapascals.

Figure 2. When compressed from above, an octahedral ceramic lattice bends reversibly, unlike bulk ceramic. One unit cell is shown (a) before and (b) after the compressive load was applied for the first time and (c) after the load was removed. In total, the lattice endured 30 cycles of compression and still recovered nearly its original shape. (Adapted from ref.

Furthermore, unlike bulk TiN, the lattices could bend significantly without breaking and spring back nearly to their original shape, even after 30 cycles of deformation. “Ceramics are not supposed to do that,” says Greer. “Imagine a piece of chalk that was bending and deforming and never breaking!”

The Caltech researchers are continuing to experiment with different lattice structures and materials, but so far their lattices are just 100 µm or so on a side. Drawing the lattice into the photoresist with a single focused laser gives them a lot of flexibility in the structures and dimensions they can achieve, but it doesn’t lend itself to mass production. As Greer explains, “That is the biggest roadblock” to developing engineering materials that capitalize on the size effect. “What someone needs to do now is develop a manufacturability route.”

References

1. M. D. Uchic et al., Science 305, 986 (2004). https://doi.org/10.1126/science.1098993

2. H. Gao et al., Proc. Natl. Acad. Sci. USA 100, 5597 (2003). https://doi.org/10.1073/pnas.0631609100

3. D. Jang et al., Nat. Mater. 12, 893 (2013). https://doi.org/10.1038/nmat3738

4. T. A. Schaedler et al., Science 334, 962 (2011).https://doi.org/10.1126/science.1211649

More about the authors

Johanna L. Miller, jmiller@aip.org